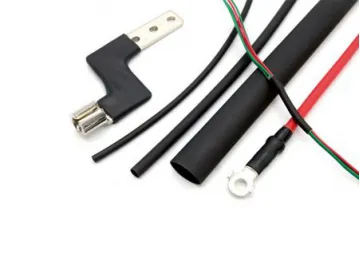

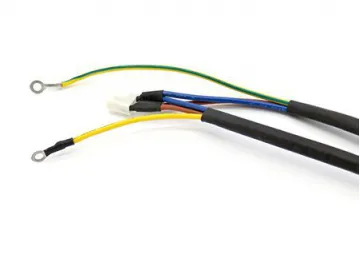

Heavy Wall Heat Shrink Tubing

Heavy Wall Heat Shrink Tubing, SBRSW Model: SBRSW Flame retardant, adhesive-lined cross-linked polyolefin heat shrinkable tubing  Features 3:1 shrink ratio Flame retardant SBRSW heavy wall heat shrink tubing will not split or rupture during installation, when overheated Thermoplastic adhesive liner for complete environmental protection and insulation Continuous operating temperature: -45℃~125℃ Fully shrink temperature: 125℃ Dimensions

Features 3:1 shrink ratio Flame retardant SBRSW heavy wall heat shrink tubing will not split or rupture during installation, when overheated Thermoplastic adhesive liner for complete environmental protection and insulation Continuous operating temperature: -45℃~125℃ Fully shrink temperature: 125℃ Dimensions

Technical Data

Adhesive

SBRSW heavy wall heat shrink tubing is flame-retardant adhesive-lined heat shrink tubing made from cross-linked polyolefin. This heat shrink tubing is ideal for insulation and protection of electrical splices and terminations where maximum flame retardancy and exceptional environmental sealing capabilities are required.

| Size (mm) | Expanded | After Recovery | Standard Package (m/pc) | |||

| Internal Diameter (mm) | Internal Diameter (mm) | Jacket Thickness (mm) | Adhesive Thickness (mm) | Total Wall Thickness (mm) | ||

| 9.0/3.0 | 9.0 | 3.0 | 2.00±0.35 | 0.45±0.20 | 2.45±0.35 | 1.22 |

| 13.0/4.0 | 13.0 | 4.0 | 2.30±0.35 | 0.45±0.20 | 2.80±0.35 | 1.22 |

| 20.0/6.0 | 20.0 | 6.0 | 2.30±0.35 | 0.60±0.20 | 2.90±0.35 | 1.22 |

| 28.0/9.0 | 28.0 | 9.0 | 2.30±0.35 | 0.70±0.20 | 3.00±0.40 | 1.22 |

| 33.0/10.2 | 33.0 | 10.2 | 2.80±0.35 | 0.70±0.20 | 3.60±0.40 | 1.22 |

| 38.1/12.0 | 38.1 | 12.0 | 3.10±0.35 | 0.70±0.20 | 3.85±0.50 | 1.22 |

| 43.2/12.7 | 43.2 | 12.0 | 3.50±0.35 | 0.70±0.20 | 4.20±0.50 | 1.22 |

| 51.0/16.0 | 55.0 | 16.0 | 3.85±0.40 | 0.70±0.20 | 4.50±0.50 | 1.22 |

| 70.0/21.0 | 75.0 | 22.0 | 3.65±0.40 | 0.70±0.20 | 4.40±0.50 | 1.22 |

| 85.0/25.0 | 85.0 | 25.0 | 3.65±0.40 | 0.70±0.20 | 4.40±0.50 | 1.22 |

| 105.0/30.0 | 105.0 | 30.0 | 3.85±0.40 | 0.70±0.20 | 4.50±0.50 | 1.22 |

| 120.0/36.0 | 120.0 | 36.0 | 3.85±0.40 | 0.70±0.20 | 4.50±0.50 | 1.22 |

| 130.0/36.0 | 130.0 | 36.0 | 3.85±0.40 | 0.70±0.20 | 4.50±0.50 | 1.22 |

| 140.0/42.0 | 140.0 | 42.0 | 3.85±0.40 | 0.70±0.20 | 4.50±0.50 | 1.22 |

| Property | Test Method | Standard Performance | Typical Performance |

| Tensile strength (MPa) | ASTM D2671 | ≥10.4 | 11.5 |

| Elongation (%) | ASTM D2671 | ≥300 | 450 |

| Tensile strength after aging (MPa) | UL224 158℃×168hr | ≥7.3 | 8.5 |

| Elongation after aging (%) | UL224 158℃×168hr | ≥200 | 350 |

| Dielectric strength (kV/mm) | IEC 60243 | ≥15 | 17.5 |

| Volume resistivity (Ω.cm) | IEC 60093 | ≥1×1014 | 2.5×1014 |

| Property | Test Method | Standard Performance |

| Water absorption | ASTM D570 | <0.2% |

| Softening point (℃) | ASTM E28 | 95±5 |

| Peel strength (PE) | ASTM D 1000 | 120N/25mm |

| Peel strength (AL) | ASTM D 1000 | 80N/25mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/1934.html

Links:https://www.globefindpro.com/products/1934.html

Recommended Products

-

Heat Shrink End Cap

Heat Shrink End Cap

-

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

-

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

-

Medium Wall Heat Shrink Tubing

Medium Wall Heat Shrink Tubing

-

Heat Shrink End Cap

Heat Shrink End Cap

-

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

-

Heavy Wall Heat Shrink Tubing

Heavy Wall Heat Shrink Tubing

-

Dual Wall Heat Shrink Tubing

Dual Wall Heat Shrink Tubing

-

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

-

Dual Wall Heat Shrink Tubing

Dual Wall Heat Shrink Tubing

-

Dual Wall Heat Shrink Tubing

Dual Wall Heat Shrink Tubing

-

Single Wall Heat Shrink Tubing

Single Wall Heat Shrink Tubing

Hot Products