Duct LineⅣ, Duct Fabrication Lines

Rectangular duct lines Ⅳ adds lockformers and flanges that are not included on duct lines II, allowing it to manufacture both TDF and TDC flanges. A duct brake is needed for TDF flange production, and a corner inserting machine is needed for TDC flange production. Our production line occupies less space, is easy to assemble or disassemble onsite, and increases productivity.

The duct line IV consists of the material compartment, duct beader, sheet shearing machine, and angle pressing machine.

Advantages:The electronics are programmable, maximum feeding speed is 16m/min, length tolerance is ±0.5mm per meter, and diagonal length tolerance is ±0.8mm.

Workflow: Uncoiling Leveling&Bending Grooving Customized Cut-off Notched "V"and "口" and Shear for C&S or TDF Flange Notched "口" and Shear for C&S or TDF Flange Forming Pittsburgh lock Forming the Angle & TDF Fangle Parameter:| Type | SBAL-Ⅳ-1250 | SBAL-Ⅳ-1550 |

| Thickness | 0.5-1.2mm | 0.5-1.2mm |

| Max-width | 1250mm | 1550mm |

| Max-working speed | 16m/min | 16m/min |

| Coiler max-weight | 8000kg | 8000kg |

| Power | 19kw | 20kw |

| Weight | 10000Kg | 12000Kg |

| Dimension | 18000×3400×1500mm | 18000×3600×1500mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/19429.html

Links:https://www.globefindpro.com/products/19429.html

Recommended Products

-

Duct LineⅤ,Automatic Rectangular Ductwork Manufacturing System

Duct LineⅤ,Automatic Rectangular Ductwork Manufacturing System

-

Gorelocker SBEM-1250

Gorelocker SBEM-1250

-

Seam Welder, Seam Welding machine

Seam Welder, Seam Welding machine

-

Swaging Machines

Swaging Machines

-

Semi Rigid Aluminum Duct Forming SBLF-500

Semi Rigid Aluminum Duct Forming SBLF-500

-

Seam Closer

Seam Closer

-

Automatic Flexible Duct Forming Machine, Aluminum Flex Ducter

Automatic Flexible Duct Forming Machine, Aluminum Flex Ducter

-

HVAC Ductwork Manufacturing Solution

HVAC Ductwork Manufacturing Solution

-

Gasket Shaper

Gasket Shaper

-

Spot Welder, Spot Welding machine

Spot Welder, Spot Welding machine

-

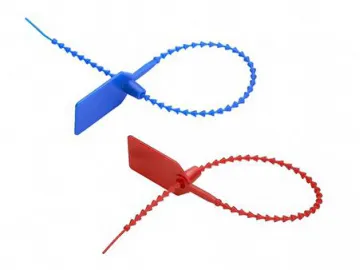

Plastic Seal CH315

Plastic Seal CH315

-

TDF flange Rollformer, TDF Cleatmaker

TDF flange Rollformer, TDF Cleatmaker