Duct LineⅤ,Automatic Rectangular Ductwork Manufacturing System

The duct line Ⅴ adds a bending machine that is not found on duct line IV. The end product is almost a fully rectangular duct that can be used immediately after the edges have been sealed with a seam closer and corners have been inserted.

The production line is fully automated, which saves labor and increases both the precision and productivity. The duct line V features a prefill angle flange former or a TDF flange former, both of which are easily interchangeable and easy to operate.

Duct line Ⅴ consists of the material compartment, flange former, duct beader, sheet shearing machine, and angle pressing machine.

Uncoiling Leveling&Bending Grooving Customized Cut-off Notched "V" and "口" and Shear for C&S or TDF Flange Notched "口" and Shear for C&S or TDF Flange Forming Pittsburgh lock Folding to "口" and "L" Type Forming the Angle & TDF Fangle Can be Forming for "L" and "口" Type Advantages: Computer controlled electronics. Bending machine powered by servo to ensure bending precision and stability. Maximum feeding speed 16m/min,length tolerence±0.5mm. Parameter:| type | Thickness Of Strip | Max-Working Speed | Working Width | Coiler Max-Weigth | Dimension | Weight |

| SBAL-ⅴ-1250 | 0.5-1.2mm | 12m/min | 1250mm | 8000Kg | 24000×3500×1500mm | 15000Kg |

| SBAL-ⅴ-1550 | 0.2-1.2mm | 12m/min | 1550mm | 8000Kg | 24000×3800×1500mm | 16000 Kg |

Scan QR to Read

Links:https://www.globefindpro.com/products/19430.html

Links:https://www.globefindpro.com/products/19430.html

Recommended Products

-

Gorelocker SBEM-1250

Gorelocker SBEM-1250

-

Seam Welder, Seam Welding machine

Seam Welder, Seam Welding machine

-

Swaging Machines

Swaging Machines

-

Semi Rigid Aluminum Duct Forming SBLF-500

Semi Rigid Aluminum Duct Forming SBLF-500

-

Seam Closer

Seam Closer

-

Power slip rolls

Power slip rolls

-

Duct LineⅣ, Duct Fabrication Lines

Duct LineⅣ, Duct Fabrication Lines

-

Automatic Flexible Duct Forming Machine, Aluminum Flex Ducter

Automatic Flexible Duct Forming Machine, Aluminum Flex Ducter

-

HVAC Ductwork Manufacturing Solution

HVAC Ductwork Manufacturing Solution

-

Gasket Shaper

Gasket Shaper

-

Spot Welder, Spot Welding machine

Spot Welder, Spot Welding machine

-

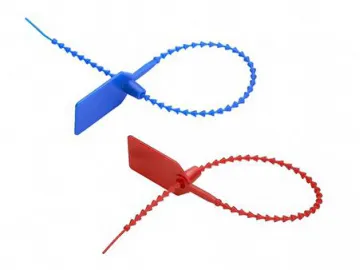

Plastic Seal CH315

Plastic Seal CH315

Hot Products