Tube Laser Cutting Machine with Automatic Loading System T230A

Introduction

The 230A tube laser cutting machine with an automatic loading system cuts metal tubes with a diameter of 20 to 230mm and a maximum length of 6500mm more efficiently.

The metal tubes will be clamped using a sensitive and stable self-centering chuck with a large clamping force and a wide clamping range, allowing the machine to cut metal tubes with different inner and outer diameters.

With the fully automatic loading and unloading device, operators can place multiple metal tubes on the loading area at once, where the metal tubes will then be automatically separated, with just one tube at a time sent to the processing area. After cutting, the finished product will be automatically separated from the scrap material.

A 1920×1080 high-definition touch screen features a touchscreen accuracy of the same levels of an IPad ensures an easy operation and high quality working efficiency.

ApplicationShelf Fitness Equipment Lighting fixture Household appliances Medical equipment Kitchenware Car seat Handcrafted gift Materials

Stainless steel Alloy steel Carbon steel Aluminum alloy Galvanized steel Copper Titanium Parameters

| Model | T230A | |

| Effective pipe cutting length | 6500mm | |

| Max. output power | 4000w/3000w/2000w/1500w/1000w | |

| Effective pipe cutting diameter | Φ20-230mm | |

| Effective square tube cutting diameter | □20*20-□160*160mm | |

| Rectangular tube | Edge length | 20-170mm |

| Max. outer circle diameter | ≤230mm | |

| X/Y-axis positioning accuracy | 0.05mm | |

| X/Y-axis repositioning accuracy | 0.03mm | |

| X axis maximum speed | 95m/min | |

| Y axis maximum speed | 70m/min | |

Links:https://www.globefindpro.com/products/20118.html

-

Dual-use Exchange Platform Laser Cutter ET

Dual-use Exchange Platform Laser Cutter ET

-

Tube and Sheet Laser Cutting

Tube and Sheet Laser Cutting

-

Our Work

Our Work

-

Acrylic Laser Cutting and Engraving

Acrylic Laser Cutting and Engraving

-

Tube and Sheet Laser Cutting Machine, F-T Series

Tube and Sheet Laser Cutting Machine, F-T Series

-

BML-FT Desktop Fiber Laser Marker

BML-FT Desktop Fiber Laser Marker

-

Precision Laser Cutting Machine i5

Precision Laser Cutting Machine i5

-

Metal Tube Laser Cutting

Metal Tube Laser Cutting

-

P Series Protective Cover

P Series Protective Cover

-

Laser Cutting Textiles

Laser Cutting Textiles

-

All Cover Dual-Use Laser Cutting Machine P-T

All Cover Dual-Use Laser Cutting Machine P-T

-

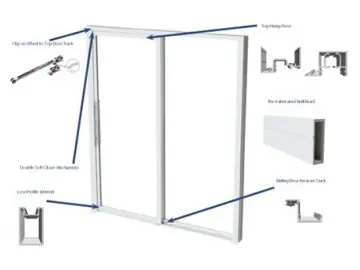

Heavy Swing Door, Hang Sliding Door

Heavy Swing Door, Hang Sliding Door