CNC Plasma Profile Cutting Machine

CNC plasma profile cutting machine can cut various metal materials efficiently, especially the low thickness conductive metal. This metal cutting machine can achieve the cutting speed as high as 12000 mm/min. With the equipment of HIWIN ball screw in drive system, the driving accuracy can be controlled in 0.05 mm, and this machine is high cost-effective and durable.

Features

The machine body is made by square tube structure with welding process and stress relieving, which is very stiff and tough. The cutting process using this kind of machine is very steady and precise. The surface of machine body is surface oxidized, which brings with high corrosive resistance and extends its working life. The frame of the machine is made by No.40 rolled steel together with surface fine grinding. Longitudinal motion is driven by bilateral drive machines, which ensures the steady and precise running. Torch lifters can be controlled by separate servo motors of motion in horizontal direction. The movable beam has enough space for 6 torch lifters which can cut simultaneously. Every torch lifter is equipped with separated cutting plasma torch and lifting structure. The torch height can be controlled automatically by command THC (controller of torch height). Parameters

| Model | NC3000, NC3500, NC4000, NC5000, NC6000 |

| Z working area | 150mm |

| Machine power | 8.5kw |

| Working voltage | 380V/50Hz/3phase |

| Reposition precision | 0.3mm |

| Processing precision | 0.1mm |

| Maximum cutting speed | 12000mm/min |

| Plasma power supply | LGK 63A |

| Cutting thickness | 6-150mm thickness for carbon steel |

| Control system | F2100-CNC control system |

| Motors | Stepper motor |

| Software | STAR cam |

| Weight | 14000 kgs |

| Plasma air pressure | Max. 0.8MPa |

| Working temperature | -10℃~60℃ relative humidity, 0-95% |

Samples

Scan QR to Read

Links:https://www.globefindpro.com/products/21640.html

Links:https://www.globefindpro.com/products/21640.html

Recommended Products

-

Metal Shear Blade

Metal Shear Blade

-

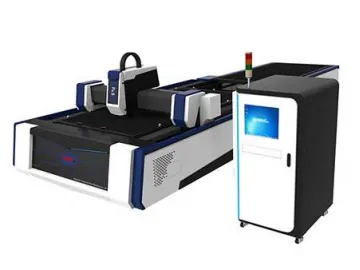

Integrated Tube and Sheet Fiber Laser Cutter with Full Cover Protection

Integrated Tube and Sheet Fiber Laser Cutter with Full Cover Protection

-

Vertical CNC V Grooving Machine

Vertical CNC V Grooving Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hydraulic Swing Beam Shearing Machine

Hydraulic Swing Beam Shearing Machine

-

Fiber laser Cutting Machine with Shuttle Table

Fiber laser Cutting Machine with Shuttle Table

-

Sheet Metal Fiber Laser Cutting Machine with Full Cover Protection

Sheet Metal Fiber Laser Cutting Machine with Full Cover Protection

-

Variable Angle Hydraulic Corner Notcher

Variable Angle Hydraulic Corner Notcher

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

Stage Lighting Moving Head LED Spot Light Code SS657SC Stage Light

Stage Lighting Moving Head LED Spot Light Code SS657SC Stage Light

-

XHD-LΦ 75/100/75x2500 CPE Cast Film Line

XHD-LΦ 75/100/75x2500 CPE Cast Film Line

-

Fully Automatic Slitter Rewinder

Fully Automatic Slitter Rewinder