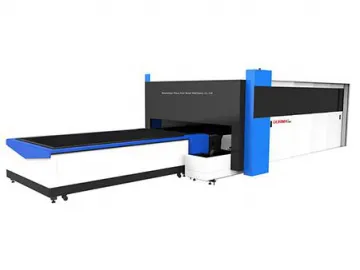

Integrated Tube and Sheet Fiber Laser Cutter with Full Cover Protection

3015HM Fiber Laser Cutter can be used for cutting sheet and tube, and this process can be controlled by computer. The functions of automatic arrangement and automatic tracing-edge improve the materials utilization and cutting efficiency in a significant way.

Gantry structure has been used in the cutting unit, and the servo motor working with gear and rack can ensure the machine to work smoothly with high cutting speed. For the cutting of the tube, the double chucks were used to grasp the working part of the tube, whose rotation is powered by servo motors, and the forward and backward position shift is also driven by gear and rack powered by servo motors. With the properties of high working efficiency and stability, this kind of machine is very suitable for cutting the sheet and the tube.

Parts

The machine body uses surrounding enclosure design to protect operators from laser radiation, dust and noises.

The double chucks were used to grasp the tube, the square tube and other kinds of tubes.

The laser head can change the laser beam focus automatically by setting the parameters to cut plates with different thickness or punch a hole efficiently, and the double water-cooling device has been installed in the laser head to protect the lens form overheating, which can keep the accuracy of focus and make the working life longer.

Parameters| Model | PS3015 PS4015 PS4020 PS6020 |

| Working Area | 3000*1500mm 4000*1500mm 4000*2000mm 6000*2000mm |

| Laser Power | 500W 800W 1000W 1500W 2000W 3000W 4000W 6000W |

| Laser Wave Length | 1064nm |

| Working Table | Sawtooth |

| Maximum Idle Running Speed | 1200mm/s |

| Position Accuracy | ±0.05mm/m |

| Position Speed | 20m/min |

| Minimum Line Width | ± 0.02mm |

| Cutting Thickness | ≤24mm |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤50KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | Lasermech made in USA |

| Focus lens | Lasermech made in USA |

| Driver system | 1500W Fuji servo motor made in Japan |

| Liner guider system | PMI made in Taiwan , (Option THK made in Japan) |

| Transmit system | Dual Rack & Pinion type |

| Rack system | made in Germany |

| Chain system | Igus made in Germany |

| Warranty time | 3 years |

Samples

Links:https://www.globefindpro.com/products/21644.html

-

Vertical CNC V Grooving Machine

Vertical CNC V Grooving Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hydraulic Swing Beam Shearing Machine

Hydraulic Swing Beam Shearing Machine

-

Fiber laser Cutting Machine with Shuttle Table

Fiber laser Cutting Machine with Shuttle Table

-

Mechanical Power Press

Mechanical Power Press

-

Fiber Laser Cutting Machine with Shuttle Table

Fiber Laser Cutting Machine with Shuttle Table

-

Metal Shear Blade

Metal Shear Blade

-

CNC Plasma Profile Cutting Machine

CNC Plasma Profile Cutting Machine

-

Sheet Metal Fiber Laser Cutting Machine with Full Cover Protection

Sheet Metal Fiber Laser Cutting Machine with Full Cover Protection

-

Variable Angle Hydraulic Corner Notcher

Variable Angle Hydraulic Corner Notcher

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

Stage Lighting Moving Head LED Spot Light Code SS657SC Stage Light

Stage Lighting Moving Head LED Spot Light Code SS657SC Stage Light