Hydraulic Ironworker, Q45Y Series

Key Parameters Q35Y Series

Main motor:Siemens - Germany Oil pipe connector:pressure hose - Germany Sealing ring:Parker - USA Technical Specifications:

Details: Structure and performance introduction: This series of products are ideal equipment for cutting all kinds of angle steel, I-beam, U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible to finish series operations simultaneously on one machine, such as punching, shearing and notching, Dual-piston-type combined punching and shearing machine allows two-man operation at the same time (stamping another work station), German Rexroth’s integrated hydraulic valve block ensures the stability of the machine, Through Thermal Effect of annealing processing, the entire rack is able to keep its shape forever, without deformation. The introduction of imported brand accessories ensures the parts ’ service life and use precision. Punching: effective punching can be achieved with the machine, and stamping die is easy to be replaced. Bar cutting: you can quickly cut the round bar and square steel, if you want to cut U-shaped, I-beam or T-profile section steel only by exchanging the cutting blade and the operation procedure is very simple. Angle cutting: you can cut several 90 ° and 45 ° angles with the help of special dies. Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work by making the bending moulds. Notching: The machine is equipped with a large-shaped slotting blade head, which can meet your general use, as to, special shaping blade head can be customized. Main functions: 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time. More efficient stroke-control functions of piston rod. Central lubricating system Motor-driven rear stopper Lighting devices for work 5 independent work-positions: punch pin and die (standard punching dies),cutting blade group for round and square steel, shearing blades for steel plate, slotting and angle-cutting blade. Sample Display:

Main motor:Siemens - Germany Oil pipe connector:pressure hose - Germany Sealing ring:Parker - USA Technical Specifications:

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | |

| Plate shearing | Shearing Pressure (Kn) | 600 | 900 | 1200 | 1600 | 2000 | 2500 |

| One stroke shears size steel flat Thickness×Width(mm) | 16×250 | 20×330 | 25×330 | 30×355 | 35×380 | 40×400 | |

| Maximum Shearing size (mm) | 8×400 | 10×480 | 16×600 | 20×600 | 25×700 | 30×750 | |

| Length of blade (mm) | 410 | 485 | 620 | 610 | 710 | 760 | |

| Blade Angle (mm) | 7 | 8 | 8 | 8 | 8 | 8 | |

| ProfileShearing | Side Length of Square Steel (mm) | 40 | 45 | 50 | 55 | 60 | 65 |

| Diameter of Round Steel (mm) | 45 | 50 | 60 | 65 | 75 | 80 | |

| Box Iron Size (mm) | 120 | 160 | 200 | 280 | 300 | 320 | |

| T Steel Size (mm) | 120 | 160 | 200 | 280 | 280 | 320 | |

| Angle Equilateral 90 °Length (mm) | 100×10 | 140×12 | 160×14 | 180×16 | 200×16 | 200×20 | |

| Die cutting | Thickness (mm) | 8 | 10 | 12 | 16 | 16 | 18 |

| Width (mm) | 57 | 80 | 80 | 60 | 100 | 120 | |

| Depth (mm) | 100 | 100 | 100 | 100 | 105 | 120 | |

| Hole Punching | Punching Force(Kn) | 600 | 900 | 1200 | 1600 | 2000 | 2500 |

| Thickness(mm) | 16 | 20 | 25 | 30 | 35 | 35 | |

| Max. Diameter (mm) | 25 | 30 | 35 | 35 | 40 | 45 | |

| Throat Depth (mm) | 300 | 355 | 400 | 600 | 550 | 550 | |

| Max. Stroke(mm) | 80 | 80 | 80 | 80 | 80 | 100 | |

| Number of Strokes | 8 | 8 | 8 | 8 | 8-24 | 8-24 | |

| Material Strength (Mpa) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| Motor | Model | Y112M2-4 | Y132M2 | Y132M4 | Y160M-4 | HYY2160L-4 | HYY2160L-4 |

| Power (KW) | 4/5.5 | 5.5/7.5 | 7.5/11 | 11/15 | 15/18.5 | 18.5/22 | |

| Speed (r/min) | 1440 | 1440 | 1440 | 1460 | 1440 | 1460 | |

| Machine Size | Length(mm) | 1650 | 1950 | 2350 | 2680 | 2800 | 3000 |

| Width (mm) | 800 | 900 | 980 | 1060 | 1160 | 1440 | |

| Height(mm) | 1780 | 1930 | 2100 | 2380 | 2400 | 2450 | |

| Gross Weight (㎏) | 1800 | 2600 | 4800 | 6800 | 9200 | 12800 | |

Scan QR to Read

Links:https://www.globefindpro.com/products/21651.html

Links:https://www.globefindpro.com/products/21651.html

Recommended Products

-

Fix Angle Hydraulic Corner Notcher

Fix Angle Hydraulic Corner Notcher

-

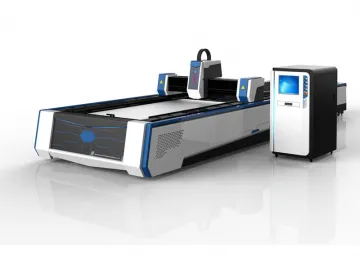

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

-

Horizontal CNC V Grooving Machine

Horizontal CNC V Grooving Machine

-

Auto Feeding Fiber Laser Cutter Used for Cutting Tube and Sheet

Auto Feeding Fiber Laser Cutter Used for Cutting Tube and Sheet

-

Press Brake Tooling

Press Brake Tooling

-

Hydraulic Guillotine Shearing Machine

Hydraulic Guillotine Shearing Machine

-

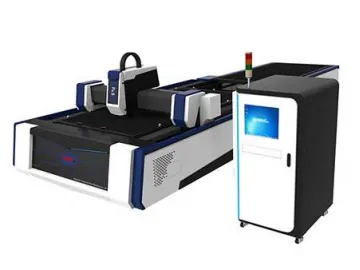

Fiber Laser Cutting Machine with Shuttle Table

Fiber Laser Cutting Machine with Shuttle Table

-

Mechanical Power Press

Mechanical Power Press

-

Fiber laser Cutting Machine with Shuttle Table

Fiber laser Cutting Machine with Shuttle Table

-

Hydraulic Swing Beam Shearing Machine

Hydraulic Swing Beam Shearing Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Vertical CNC V Grooving Machine

Vertical CNC V Grooving Machine