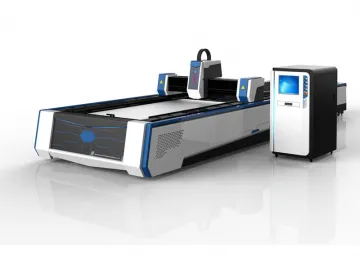

Auto Feeding Fiber Laser Cutter Used for Cutting Tube and Sheet

Auto feeding fiber laser cutter used for cutting tube and sheet with open structure comprises two parts of sheet cutting and tube cutting, which is ideal for cutting of metal sheet and tube. The part of sheet cutting uses gantry structure together with gear and rack, which is not only stable and tough, but it also is with high processing precision. The double chucks were used to grasp the working part of the tube, whose rotation is powered by servo motors, and the forward and backward position shift is also driven by gear and rack powered by servo motors with high controlling precision.

With power as high as 500 W-6000 W, this kind of laser cutting machine can cut all kinds of metal materials including 0.5-24 mm carbon steel sheet / tube, 0.5-3 mm galvanized sheet / tube, 0.5-14 mm aluminum alloy sheet / tube, 0.5-10 mm brass sheet / tube and other low thickness metal materials.

DetailsThis kind of fiber cutting machine has automatic shuttle table. It only takes 15 seconds for loading with high efficiency, which reduces the time consumption and labor cost.

With automatic focusing fiber laser cutting head, the operators can adjust the focus only by set up the parameters to process the high-speed punching and automatic cutting.

The electric double chucks were used to grasp the working part of the tube, which can process the tube, square tube and all kinds of special pipe.

The welding process of the fiber laser cutter is followed by high-temperature tempering, which can reduce the stress of welding and processing and decrease machining error caused by machine vibration.

Parameters| Model | PS3015 PS4015 PS4020 PS6020 |

| Working Area | 3000*1500mm 4000*1500mm 4000*2000mm 6000*2000mm |

| Laser Power | 500W 800W 1000W 1500W 2000W 3000W 4000W 6000W |

| Laser Wave Length | 1064nm |

| Working Table | Sawtooth |

| Maximum Idle Running Speed | 1200mm/s |

| Position Accuracy | ±0.05mm/m |

| Position Speed | 20m/min |

| Minimum Line Width | ± 0.02mm |

| Cutting Thickness | ≤24mm |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤50KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | Lasermech made in USA |

| Focus lens | Lasermech made in USA |

| Driver system | 1500W Fuji servo motor made in Japan |

| Liner guider system | PMI made in Taiwan , (Option THK made in Japan) |

| Transmit system | Dual Rack & Pinion type |

| Rack system | made in Germany |

| Chain system | Igus made in Germany |

| Warranty time | 3 years |

Samples

Links:https://www.globefindpro.com/products/21657.html

-

Press Brake Tooling

Press Brake Tooling

-

Hydraulic Guillotine Shearing Machine

Hydraulic Guillotine Shearing Machine

-

Hydraulic Press Machine for Steel Door Skin Embossing

Hydraulic Press Machine for Steel Door Skin Embossing

-

CNC plasmas cutter, CNC Oxy-fuel Cutting Machine

CNC plasmas cutter, CNC Oxy-fuel Cutting Machine

-

Profile Bending Machine

Profile Bending Machine

-

YDST Series Diesel Oil Burner Barrel Melter, Bitumen Drum Decanter

YDST Series Diesel Oil Burner Barrel Melter, Bitumen Drum Decanter

-

Horizontal CNC V Grooving Machine

Horizontal CNC V Grooving Machine

-

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

-

Fix Angle Hydraulic Corner Notcher

Fix Angle Hydraulic Corner Notcher

-

Hydraulic Ironworker, Q45Y Series

Hydraulic Ironworker, Q45Y Series

-

Fiber Laser Cutting Machine with Shuttle Table

Fiber Laser Cutting Machine with Shuttle Table

-

Mechanical Power Press

Mechanical Power Press