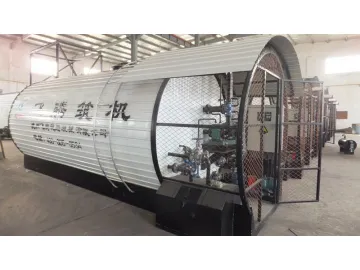

Asphalt Emulsion Plant

Feiteng’s asphalt emulsion plant is tailor-made for manufacturing emulsified common asphalt and modified asphalt, which are primarily used for slurry seals or micro-surfacing treatment.

In the emulsification process, the melted bitumen is dispersed mechanically in a solution of water stabilized with surfactant — or commonly known as emulsifying agent or emulsifier. The size of emulsified asphalt droplets is generally as small as 0.1μm.

Substances involved: melted asphalt, water, emulsifier, etc.;

Production process: with a specific ratio of asphalt and emulsifying solution, emulsified asphalt is produced by passing through a colloid mill for breaking asphalt into small droplets. Then final emulsified asphalt products will be cooled, and loaded for transportation.

Heating method: there are electric heating, thermal oil heating and oil-fired boiler for you to choose. In addition, specifically designed asphalt heating and storage tanks are also available for facilitate heating and storing asphalt, as well as produce high temperature thermal oil. It is a perfect solution for you to heat up piping circuit and water used in emulsified asphalt production process.

| Model | Production capacity (t/h) | Fitness | Proportion adjustment range | Proportional control precision | Total power (kw) | Dimensions (L×W×H) |

| RL-6 | 4-6 | 1-5 | 10%-70% | 1% | 34 | 6x2.2x2.5 |

| RL-10 | 10-12 | 1-5 | 10%-70% | 1% | 42 | 6x2.2x2.5 |

| GRL-6 | 6-10 | 1-5 | 10-70% | 1% | 34 | 6.8×2.2×2.53 |

| GRL-10 | 10-12 | 1-5 | 10-70% | 1% | 42 | 7×2.2×2.53 |

| QRL-6 | 6-10 | 1-5 | 10-70% | 1% | 34 | 6.8×2.2×2.53 |

| QRL-10 | 10-12 | 1-5 | 10-70% | 1% | 42 | 7×2.2×2.53 |

Performance parameters

| Model | RL-6 | RL-10 | GRL-6 | GRL-10 | QRL-6 | QRL-10 |

| Configuration | basic configuration | basic configuration | medium configuration | medium configuration | high configuration | high configuration |

| Production capacity (t/h) | 4-6 | 8-10 | 6-8 | 10-12 | 6-8 | 10-12 |

| Asphalt type | common asphalt | common asphalt | SBS modified asphalt | |||

| Tank material | stainless steel tank | stainless steel tank | RPP plastic tank (corrosion-resistant) | |||

| Emulsifier pipe material | carbon steel | carbon steel | RPP pipe fittings (corrosion-resistant), stainless steel pipe fittings (acid and alkali resistant) | |||

| Asphaltpumping | adjustable-speed drive | adjustable-speed drive | variable frequency drive | variable frequency drive | variable frequency drive | variable frequency drive |

| Emulsification equipment | colloid mill | colloid mill | emulsion mill | emulsion mill | emulsion mill | emulsion mill |

| Finished product processing | transition tank for finished product temporary storage and sampling | heat exchanger for reducing the temperature of emulsified asphalt, and prolong storage time | ||||

| Finished product content detection | no | no | yes | |||

| Control mode | manual | manual | manual | manual | automatic | |

| Machine structure | skid mount | skid mount | skid mounted or containerized (optional) | |||

| Dimension (L×W×H) | Max. 7000×2200×2530mm, can be placed in 40 foot shipping container, can be shipped by land or sea | |||||

The solid content detection unit is able to display finished emulsified asphalt proportion directly without flow meter. Through three sets of temperature sensors, so asphalt temperature, emulsifier temperature, and finished product temperature can be obtained by use of dynamic solid content algorithm. High efficiency heat exchanger is equipped:

Using heat exchanger for cooling finished emulsified asphalt increases stability of asphalt storage. Simultaneously, cooling water can be re-heated for production process of emulsified asphalt. In simple terms, only first tank of water need to be heated, then water used for subsequent production processes are all heated by heat exchanger. Fully automatic controlling by PLC system;

Links:https://www.globefindpro.com/products/21686.html

-

Metallurgical Industry

Metallurgical Industry

-

Heating and Melting Equipment for Corrosive Materials

Heating and Melting Equipment for Corrosive Materials

-

Four Column Hydraulic Press

Four Column Hydraulic Press

-

Asphalt / Bitumen Tank Trailer

Asphalt / Bitumen Tank Trailer

-

YDLR Series Bag Asphalt Melting Equipment

YDLR Series Bag Asphalt Melting Equipment

-

Heating and Storing Asphalt Using Electric Heater

Heating and Storing Asphalt Using Electric Heater

-

Solar Roof Mounting System

Solar Roof Mounting System

-

Ductile Iron Wear Resistant Casings

Ductile Iron Wear Resistant Casings

-

Hydraulic Rolling Machine With 4 Rollers

Hydraulic Rolling Machine With 4 Rollers

-

Quarring

Quarring

-

Asphalt Mixing and Paving

Asphalt Mixing and Paving

-

Asphalt Storage and Heating Tank

Asphalt Storage and Heating Tank