Vaccum Drying Oven (Two Shelf)

Main technical parameter index(can be measured at an ambient temperature of +5 to +35 °C)

Structure

Working chamber size: 850mm height, 800mm width, 1600mm depth. Effective working size: 590mm height, 660mm width, 1600mm depth. 2 chambers. Dimensions: Refer to the schematic diagram. Insulation thickness: 90mm. Supporting foot: 100mm. Heater position: Around the inside of the cavity. Pumping port position: 2 chambers are concentrated in one suction port and vacuumed, controlled by solenoid valve Venting port position: Equipped with inflatable solenoid valve. Opening method: 2 single doors. Control box position: Right side. Silicone Rubber high temperature resistance sealing ring. Equipped with water cooling cycle system. Each chamber is equipped with a stainless steel trolley, a small wheel with a universal wheel, and each trolley with 2 directional wheels. Each chamber has a blast wheel on the back, magnetic fluid connection.

Main Property

Working temperature: Room temperature +15 ° C ~ 180 ° C Instrument accuracy: ±1℃ Temperature uniformity: ±2°C (empty box, 120°C, 2 hours after stable) Heating time: ≤40min(empty box,25℃~150℃) Temperature control method: PID adjustment Vacuum degree: ≥100Pa (0.0999MPa) average air leakage in 24 hours: ≤0.5kPa/h; Outside surface temperature: ≤ room temperature +20 ° C

Electrical capacity:

Power supply: AC380V 3-phase 4-wire 50Hz Heating power: 12KW*2 Blast power: 370W*2 Maximum current: 20A*2 Air switch capacity:50A

Security devices:

Air switch (prevent overcurrent and short circuit) Overcurrent protection (prevent high current) Over temperature protection (prevent high temperature, protect the product), Over temperature alarm.

Functional requirements

Program control, color LCD touch screen display settings Equipped with 2 electromagnetic valves, and vacuuming, holding pressure, inflation processes are all program controlled and automatic. Users can freely adjust the vacuum degree and temperature, and automatically maintain them under a specific temperature and vacuum degree range. Equipment operation processes (vacuum, holding pressure, inflation) are automatically PLC controlled.

Structure

Working chamber size: 850mm height, 800mm width, 1600mm depth. Effective working size: 590mm height, 660mm width, 1600mm depth. 2 chambers. Dimensions: Refer to the schematic diagram. Insulation thickness: 90mm. Supporting foot: 100mm. Heater position: Around the inside of the cavity. Pumping port position: 2 chambers are concentrated in one suction port and vacuumed, controlled by solenoid valve Venting port position: Equipped with inflatable solenoid valve. Opening method: 2 single doors. Control box position: Right side. Silicone Rubber high temperature resistance sealing ring. Equipped with water cooling cycle system. Each chamber is equipped with a stainless steel trolley, a small wheel with a universal wheel, and each trolley with 2 directional wheels. Each chamber has a blast wheel on the back, magnetic fluid connection.

Main Property

Working temperature: Room temperature +15 ° C ~ 180 ° C Instrument accuracy: ±1℃ Temperature uniformity: ±2°C (empty box, 120°C, 2 hours after stable) Heating time: ≤40min(empty box,25℃~150℃) Temperature control method: PID adjustment Vacuum degree: ≥100Pa (0.0999MPa) average air leakage in 24 hours: ≤0.5kPa/h; Outside surface temperature: ≤ room temperature +20 ° C

Electrical capacity:

Power supply: AC380V 3-phase 4-wire 50Hz Heating power: 12KW*2 Blast power: 370W*2 Maximum current: 20A*2 Air switch capacity:50A

Security devices:

Air switch (prevent overcurrent and short circuit) Overcurrent protection (prevent high current) Over temperature protection (prevent high temperature, protect the product), Over temperature alarm.

Functional requirements

Program control, color LCD touch screen display settings Equipped with 2 electromagnetic valves, and vacuuming, holding pressure, inflation processes are all program controlled and automatic. Users can freely adjust the vacuum degree and temperature, and automatically maintain them under a specific temperature and vacuum degree range. Equipment operation processes (vacuum, holding pressure, inflation) are automatically PLC controlled.

Scan QR to Read

Links:https://www.globefindpro.com/products/22303.html

Links:https://www.globefindpro.com/products/22303.html

Recommended Products

-

Cooled Vacuum Oven

Cooled Vacuum Oven

-

PVC Marble Flooring

PVC Marble Flooring

-

Air Conditioner Tube Connector

Air Conditioner Tube Connector

-

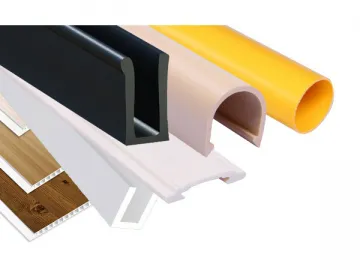

Custom Plastic Extrusions

Custom Plastic Extrusions

-

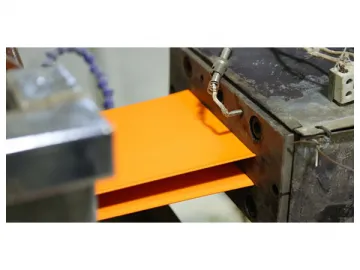

Extruded PVC Panels

Extruded PVC Panels

-

Electronics Enclosure

Electronics Enclosure

-

Vacuum Oven (Four Shelf)

Vacuum Oven (Four Shelf)

-

Cleanroom Drying Oven in LCD Applications

Cleanroom Drying Oven in LCD Applications

-

Battery Industrial Vacuum Ovens

Battery Industrial Vacuum Ovens

-

Vaccum Drying Chamber (Single Shelf)

Vaccum Drying Chamber (Single Shelf)

-

Vacuum Oven especially used for Photoelectric

Vacuum Oven especially used for Photoelectric

-

Vacuum Oven (Three Shelf)

Vacuum Oven (Three Shelf)

Hot Products