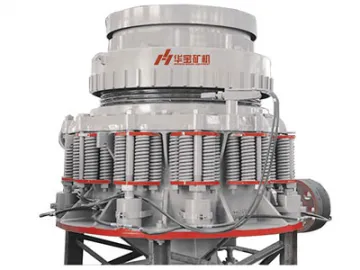

Symons Cone Crusher, Mining and Quarry Crusher

The symons efficient cone crusher is designed according to customer requirements, and is based on the laminating crushing process, with the idea to “crush more, grind less”. This means that materials that pass through the equipment feature a fine proportion and are in a cubic structure. This equipment features complete cavity specifications, which include an extra coarse, coarse, medium, and fine cavity for customers to choose from in order to adapt to a wide array of feeding conditions and particle size demands for different products.

This crusher features a reliable overload protection device in the motor system, which includes an oil temperature, oil pressure and oil mass range alarm system. These security features are designed to prevent major accidents and protect employees.

ApplicationThe cone crusher is used to crush nonferrous metals, granite, limestone, quartzite, cobblestones and more in metal or nonmetal, cement plants, buildings, sand metallurgy and other industries.

ParameterProperty parameters of standard cone crusher open process:

| Model | Cavity model | Recommended minimum discharge opening Amm | Feed opening correspond with the recommended minimum discharge opening A | Production capacity correspond with discharge opening t/h | Main motor (KW) | |||||||||||||

| Bmm closed | Bmm opening | 9 | 13 | 16 | 19 | 22 | 25 | 31 | 38 | 51 | 64 | 76 | 89 | 102 | ||||

| S75B | Fine | 9 | 83 | 102 | 45 | 59 | 72 | 81 | 91 | 75 | ||||||||

| coarse | 13 | 159 | 175 | 59 | 72 | 91 | 109 | 118 | 136 | 163 | ||||||||

| Extra coarse | 25 | 163 | 178 | 128 | 147 | 175 | 196 | |||||||||||

| S155B | Fine | 13 | 109 | 137 | 109 | 127 | 145 | 154 | 163 | 181 | 185 | |||||||

| Medium | 16 | 188 | 210 | 132 | 159 | 172 | 200 | 227 | 253 | 309 | ||||||||

| Coarse | 19 | 216 | 241 | 172 | 195 | 218 | 249 | 295 | 378 | |||||||||

| Extra coarse | 25 | 238 | 259 | 236 | 276 | 324 | 398 | 455 | ||||||||||

| S240B | Fine | 15 | 188 | 209 | 181 | 204 | 227 | 258 | 295 | 327 | 240 | |||||||

| Medium | 22 | 213 | 241 | 258 | 290 | 336 | 381 | 437 | 437 | |||||||||

| Coarse | 25 | 241 | 269 | 354 | 417 | 454 | 610 | 610 | ||||||||||

| Extra coarse | 38 | 331 | 368 | 538 | 630 | 743 | ||||||||||||

| S400B | Fine | 19 | 253 | 278 | 381 | 408 | 499 | 617 | 726 | 852 | 1036 | 400 | ||||||

| Medium | 25 | 303 | 334 | 608 | 726 | 807 | 998 | 1128 | 1296 | |||||||||

| Coarse | 31 | 334 | 369 | 789 | 844 | 1088 | 1257 | 1386 | 1450 | |||||||||

| Extra | 38 | 425 | 460 | 880 | 1179 | 1361 | 1473 | 1531 | 1643 | |||||||||

Property parameters of short-head cone crusher open process:

| Model | Cavity | Recommended minimum discharge opening Amm | Feed opening correspond with the recommended minimum discharge opening A | Production capacity correspond with discharge opening t/h | Main motor (KW) | |||||||||||

| Bmm closed | Bmm opening | 3 | 5 | 6 | 10 | 13 | 16 | 19 | 25 | 29 | 32 | 38 | ||||

| S75D | Fine | 3 | 13 | 41 | 27 | 41 | 54 | 68 | 90 | 75 | ||||||

| Coarse | 3 | 33 | 60 | 27 | 41 | 54 | 68 | 90 | 100 | |||||||

| Extra coarse | 6 | 51 | 76 | 59 | 73 | 95 | 113 | 127 | ||||||||

| S155D | Fine | 3 | 29 | 64 | 36 | 59 | 82 | 104 | 136 | 163 | 185 | |||||

| Medium | 6 | 54 | 89 | 82 | 104 | 136 | 163 | |||||||||

| Coarse | 8 | 70 | 105 | 109 | 159 | 181 | 200 | 227 | ||||||||

| Extra coarse | 16 | 98 | 133 | 209 | 236 | |||||||||||

| S240D | Fine | 5 | 35 | 70 | 90 | 136 | 163 | 209 | 240 | |||||||

| Medium | 6 | 54 | 89 | 136 | 163 | 209 | 253 | 281 | ||||||||

| Coarse | 10 | 98 | 133 | 190 | 253 | 281 | 308 | 336 | ||||||||

| Extra coarse | 13 | 117 | 133 | 253 | 281 | 308 | 336 | |||||||||

| S400D | Fine | 5 | 51 | 105 | 190 | 270 | 354 | 360 | 408 | 475 | 512 | 400 | ||||

| medium | 10 | 95 | 133 | 345 | 408 | 454 | 508 | 560 | 613 | |||||||

| Coarse | 13 | 127 | 178 | 454 | 480 | 540 | 599 | 661 | 685 | |||||||

| Extra coarse | 16 | 152 | 203 | 508 | 590 | 653 | 680 | 693 | 720 | |||||||

Property parameters of standard cone crusher closed process:

| Model | Cavity | Recommended minimum discharge opening Amm | Feed opening correspond with the recommended minimum discharge opening A | Effective square hole of circular screen mm | |||||||||

| 10 | 13 | 16 | 19 | 22 | 25 | 3142 | 38 | 50 | |||||

| Bmm closed | Bmm opening | Recommended closed side discharge opening of closed process mm | |||||||||||

| 10 | 10 | 13 | 16 | 19 | 19 | 22 | 25 | 232 | |||||

| I II | I II | I II | I II | I II | I II | I II | I II | I II | |||||

| S75B | Fine | 9 | 83 | 102 | 32 59 | 36 63 | 41 68 | 54 81 | 63 95 | 72 95 | 86 108 | 108 135 | 131 153 |

| Coarse | 13 | 159 | 175 | 41 68 | 54 81 | 68 99 | 77 99 | 90 113 | 108 135 | 131 153 | |||

| Extra coarse | 25 | 163 | 178 | 68 99 | |||||||||

| S155B | Fine | 13 | 109 | 137 | 86 122 | 95 140 | 131 167 | 131 171 | 158 198 | 185 225 | |||

| Medium | 16 | 188 | 210 | 108 158 | 122 180 | 140 185 | 171 212 | 194 234 | 212 252 | ||||

| Coarse | 19 | 216 | 241 | 126 189 | 149 194 | 171 221 | 198 243 | 225 266 | |||||

| Extra coarse | 25 | 238 | 259 | 203 248 | 234 279 | ||||||||

| S240B | Fine | 15 | 188 | 209 | 144 212 | 162 239 | 189 243 | 216 270 | 270 324 | ||||

| Medium | 22 | 213 | 241 | 225 279 | 279 338 | 297 351 | |||||||

| Coarse | 15 | 241 | 269 | 286 342 | 306 360 | ||||||||

| Extra coarse | 38 | 331 | 368 | 315 369 | |||||||||

| S400B | Fine | 19 | 253 | 278 | |||||||||

| Medium | 25 | 303 | 334 | ||||||||||

| Coarse | 31 | 334 | 369 | ||||||||||

| Extra coarse | 38 | 425 | 460 | ||||||||||

Property parameters of short-head cone crusher closed process:

| Model | Cavity | Recommended minimum discharge opening Amm | Feed opening correspond with the recommended minimum discharge opening A | Effective square hole of circular screen mm | ||||||||

| 3 | 5 | 6 | 10 | 13 | 16 | 19 | 25 | |||||

| Bmm closed | Bmm closed | Recommended closed side discharge opening of closed process mm | ||||||||||

| 3 | 5 | 5 | 6 | 10 | 13 | 16 | 19 | |||||

| I II | I II | I II | I II | I II | I II | I II | I II | |||||

| S75B | Fine | 9 | 83 | 102 | 14 27 | 18 36 | 27 40 | 45 59 | 63 77 | 72 99 | ||

| Coarse | 13 | 159 | 175 | 14 27 | 18 36 | 27 40 | 45 59 | 63 77 | 72 99 | 86 122 | ||

| Extra coarse | 25 | 163 | 178 | 50 63 | 68 81 | 77 104 | 95 131 | 117 135 | ||||

| S155B | Fine | 13 | 109 | 137 | 18 36 | 32 63 | 50 72 | 68 99 | 90 117 | 113 153 | ||

| Medium | 16 | 188 | 210 | 72 108 | 95 126 | 113 153 | ||||||

| Coarse | 19 | 216 | 241 | 95 135 | 126 180 | 158 225 | 180 234 | |||||

| Extra coarse | 25 | 238 | 259 | 158 225 | 180 234 | |||||||

| S240B | Fine | 15 | 188 | 209 | 59 117 | 81 126 | 122 180 | 158 198 | 189 243 | |||

| Medium | 22 | 213 | 241 | 122 180 | 158 198 | 189 243 | 221 315 | 252 306 | ||||

| Coarse | 15 | 241 | 269 | 162 216 | 198 252 | 225 324 | 288 347 | |||||

| Extra coarse | 38 | 331 | 368 | 198 252 | 225 324 | 288 256 | ||||||

| S400B | Fine | 19 | 253 | 278 | 108 216 | 144 207 | 216 324 | 284 351 | 324 405 | 378 450 | ||

| Medium | 25 | 303 | 334 | 284 378 | 324 450 | 378 495 | 450 540 | |||||

| Coarse | 31 | 334 | 369 | 342 486 | 405 585 | 495 594 | ||||||

| Extra coarse | 38 | 425 | 460 | 419 612 | 495 621 | |||||||

Links:https://www.globefindpro.com/products/22905.html

-

Secondary Cone Crusher

Secondary Cone Crusher

-

Square Semi-Flush Mount Tower Clock

Square Semi-Flush Mount Tower Clock

-

Gyratory Crusher

Gyratory Crusher

-

Heavy Duty Jaw Crusher

Heavy Duty Jaw Crusher

-

Cone Crusher CH Series, Aggregate Crusher

Cone Crusher CH Series, Aggregate Crusher

-

Heavy Duty Hammer Crusher

Heavy Duty Hammer Crusher

-

Flush Mount Tower Clock with Arabic Numerals

Flush Mount Tower Clock with Arabic Numerals

-

Acrylic Dial Tower Clock with LED Light

Acrylic Dial Tower Clock with LED Light

-

Round Surface Double Dial Tower Clock

Round Surface Double Dial Tower Clock

-

Dry Sand Making System

Dry Sand Making System

-

Cone Crusher H Series, Multi-Cylinder Hydraulic Cone Crusher

Cone Crusher H Series, Multi-Cylinder Hydraulic Cone Crusher

-

Cyclone Sand Washer, Hydrocyclone Sand Separators

Cyclone Sand Washer, Hydrocyclone Sand Separators