99.5% Concentration Methylal Plant

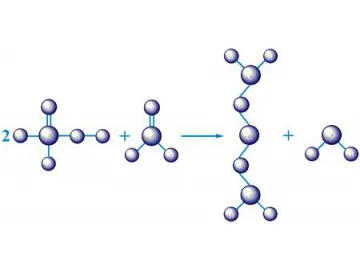

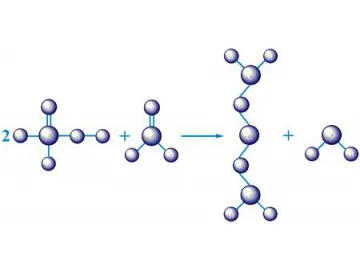

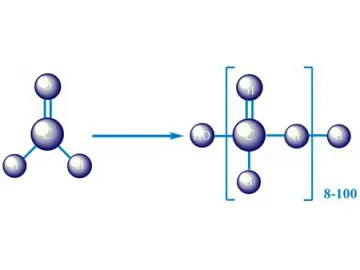

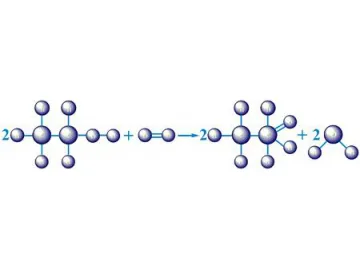

Description of Methylal Production Process  Flow chart Main Equipment for 99.5% Concentration Process Condenser Reboiler Pre-reactor Reachion tower Rectifying tower Reflux drum Pressurized tower Condenser Production Process Produce 90% concentration methylal. Condense 90% concentration methylal to 99.5% concentration.

Flow chart Main Equipment for 99.5% Concentration Process Condenser Reboiler Pre-reactor Reachion tower Rectifying tower Reflux drum Pressurized tower Condenser Production Process Produce 90% concentration methylal. Condense 90% concentration methylal to 99.5% concentration.

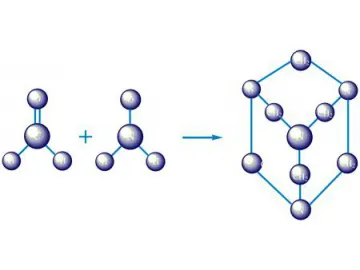

Due to the azeotrope from methylal, formaldehyde and water, normal rectification methods do not achieve a high methylal concentration. Based on the original process for normal concentrations, after researching, numerous tests and multiple technical designs, we successfully created a high concentration methylal process, ensuring the methylal purity reaches up to 99.5%.

Annotation: for more information about the production process, please do not hesitate to contact us.

Consumption index| Item | Consumption quota | Remarks |

| Raw material and auxiliary material | ||

| Formaldehyde(37%) | 1.06t/t | |

| methanol(99.5%) | 0.84t/t | |

| Utilities | ||

| Industrial feeding water t≤25℃ | Intermittent flushing | |

| Circulating water t≤32℃,△t=8℃, Circulating quantity per hour | 115.2t/t | |

| Power(380V) | 60kWh/t | |

| Low pressure steam P=0.25MPa(G) | 750kg/t | |

| Medium pressure steam P=0.8MPa(G) | 550kg/t | |

Projects Were Work on

Scan QR to Read

Links:https://www.globefindpro.com/products/22918.html

Links:https://www.globefindpro.com/products/22918.html

Recommended Products

-

Spray Dryer Paraformaldehyde Plant

Spray Dryer Paraformaldehyde Plant

-

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

-

Acetaldehyde Plant

Acetaldehyde Plant

-

Filter Press

Filter Press

-

Conveying Vibratory Feeder

Conveying Vibratory Feeder

-

Vibrating Screen USL Series Linear Screen Machine

Vibrating Screen USL Series Linear Screen Machine

-

37%-42% Concentration Absorption Tower

37%-42% Concentration Absorption Tower

-

Liquid Phase Hexamine Plant

Liquid Phase Hexamine Plant

-

Roots Blower

Roots Blower

-

Heavy Duty Hammer Crusher

Heavy Duty Hammer Crusher

-

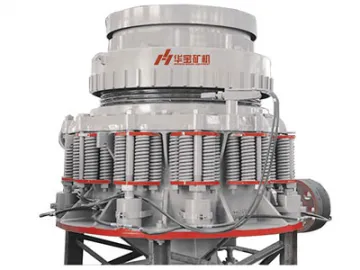

Cone Crusher CH Series, Aggregate Crusher

Cone Crusher CH Series, Aggregate Crusher

-

Heavy Duty Jaw Crusher

Heavy Duty Jaw Crusher

Hot Products