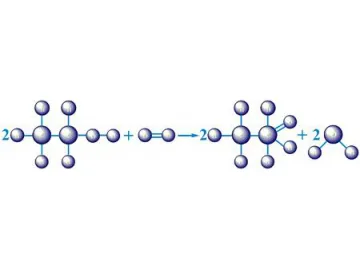

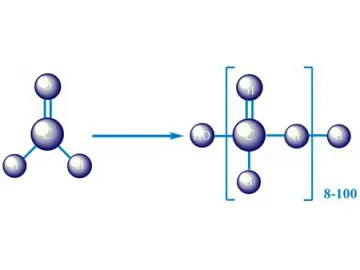

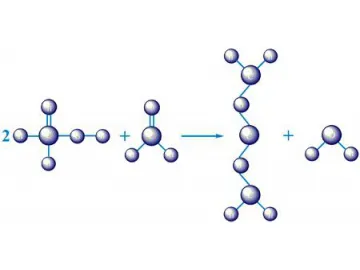

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

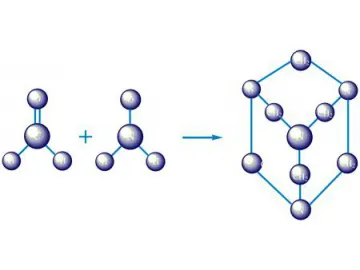

HO-[-CH2-NH-CO-NH-CH2-O]n-H  Flow chart Main Equipment of UF MUF Resin Glue Plant Resin stirring kettle. High efficiency cooler. Electrical control system. Production Process of UF MUF Resin Glue Plant Addition phase. First polycondensation. Second polycondensation. Annotation The amount of added Poly (vinyl alcohol), melamine, additives and ammonia, with PH value, temperature, reaction period and insulation period are different based on the needed glue environmental protection level and the matched wood material. Please be flexible in your decision. For more information on the production process, please do not hesitate to contact us. Specifications

Flow chart Main Equipment of UF MUF Resin Glue Plant Resin stirring kettle. High efficiency cooler. Electrical control system. Production Process of UF MUF Resin Glue Plant Addition phase. First polycondensation. Second polycondensation. Annotation The amount of added Poly (vinyl alcohol), melamine, additives and ammonia, with PH value, temperature, reaction period and insulation period are different based on the needed glue environmental protection level and the matched wood material. Please be flexible in your decision. For more information on the production process, please do not hesitate to contact us. Specifications

Raw Material and Utility Specifications

UF MUF resin glue plants are used to produce two adhesive types: UF (urea formaldehyde resin) and MUF (melamine modified urea formaldehyde resin). We supply artificial board manufacturers with the one stop services, from technical design and product design, all the way to equipment installation tests.

| S/N | Item | Index | |||

| UF RESIN E2 | MUF RESIN E2 | UF RESIN E1 | UF RESIN E0 | ||

| 1 | Appearance | Semi opaque viscous liquid | |||

| 2 | Viscosity at 30 ° C | 200-250 cps | 200 cps | 50-200 | 180 cps |

| 3 | Solids Content at 2hr/120oC | 49-51% | 56% | 50-54% | 54% |

| 4 | Specific Gravity at 30oC | 1.180-1.200 | 1.21 | 1.18-1.20 | 1.205 |

| 5 | pH at 30oC | 8.0-9.0 | 8.75 | 7.0-8.0 | 9.00 |

| 6 | Gel time | 30-40 sec | 50 sec | 50-90 sec | 200 sec |

| Material / Utility | Value |

| Formaldehyde | 37%-52% |

| Urea | 46.5% |

| Melamine | 99.8% |

| Process water(spare) | 500kg/h |

| 0.3Mpa | |

| Colling water (required for cooling, intermittent supply) | 250m3/h |

| 31°C | |

| 0.3Mpa | |

| Low pressure steam (Required for start and dehydration, intermittent supply) | 2500kg/h |

| 0.6Mpa | |

| Instrument air | 28Nm3/h |

| 0.4Mpa | |

| Electrical power | install219kW |

| employ170kW |

Scan QR to Read

Links:https://www.globefindpro.com/products/22921.html

Links:https://www.globefindpro.com/products/22921.html

Recommended Products

-

Acetaldehyde Plant

Acetaldehyde Plant

-

Filter Press

Filter Press

-

Conveying Vibratory Feeder

Conveying Vibratory Feeder

-

Vibrating Screen USL Series Linear Screen Machine

Vibrating Screen USL Series Linear Screen Machine

-

DMMn Plant

DMMn Plant

-

Vibrating Screen DYS Series Circular Motion Screen

Vibrating Screen DYS Series Circular Motion Screen

-

Spray Dryer Paraformaldehyde Plant

Spray Dryer Paraformaldehyde Plant

-

99.5% Concentration Methylal Plant

99.5% Concentration Methylal Plant

-

37%-42% Concentration Absorption Tower

37%-42% Concentration Absorption Tower

-

Liquid Phase Hexamine Plant

Liquid Phase Hexamine Plant

-

Roots Blower

Roots Blower

-

Heavy Duty Hammer Crusher

Heavy Duty Hammer Crusher

Hot Products