Acetaldehyde Plant

Description of Acetaldehyde Production Process  Flow chart Main Equipment for Acetaldehyde Plant Evaporator Oxidation tower Absorption tower Production Process Mix the alcohol material. After removing impurities such as dust via air filter, the outside air enters the evaporator via the roots blower. Mixed alcohol and air react in the evaporator and generate acetaldehyde. Cool down the acetaldehyde and unreacted alcohol. Rectify the acetaldehyde.

Flow chart Main Equipment for Acetaldehyde Plant Evaporator Oxidation tower Absorption tower Production Process Mix the alcohol material. After removing impurities such as dust via air filter, the outside air enters the evaporator via the roots blower. Mixed alcohol and air react in the evaporator and generate acetaldehyde. Cool down the acetaldehyde and unreacted alcohol. Rectify the acetaldehyde.

Projects Were Work on

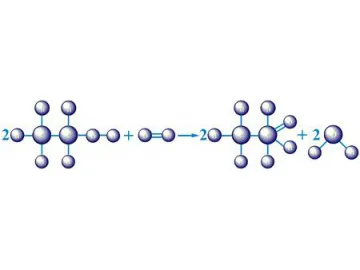

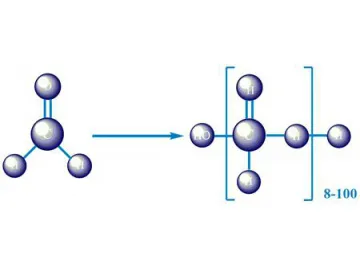

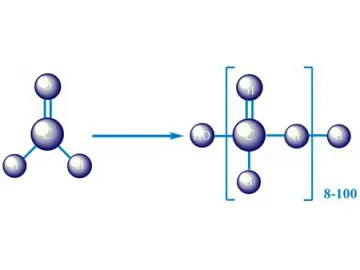

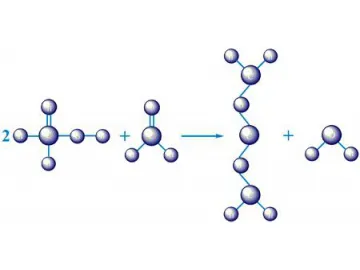

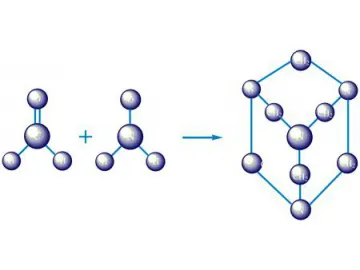

Acetaldehyde production includes 3 primary process: acetylene hydration, ethylene oxidation, and alcohol oxidation. Helipont currently utilizes the alcohol oxidation process for the production acetaldehyde, because alcohol features a low costs and a wide usage range. It also features a low conversion rate. We use double towers for absorption- one tower for circulation absorption, and the other for a spraying absorption and recycling plant in order to obtain the best consumption.

Annotation: for more information, please do not hesitate to contact us.

Performance| Name | Specification and Composition | Consumption quota |

| Alcohol | ≥95% | 1.170t/t |

| Name | Specification and Composition | 4.3t/t |

| Process Water | 25PPM(5℃)Chloridion | 6t/t |

| Steam | 0.8MPa(Gauge) | 3.0t/t |

| Instrument Compressed Gas | 0.6MPa(Gauge) | 7m3/t |

| Circulating Cooling Water | Water Inlet30℃, Water Outlet38℃, Water Pressure 0.35MPa | 410t/t |

| Chilled Water | Water Inlet7℃, Water Outlet12℃ | 160×104KJ/t |

| Electric | 380V 50Hz | 250KWH/t |

| Waste Water | Ethanol 0.03%, Acidity 0.25%, COD5000ppm, BOD2000ppm | 5t/t |

| Exhaust Gas | Acetaldehyde≤0.1%, CO+CO2 ≤0.8%, H2+ CH4 ≤1.2%, H2O≤1%, N2≥96% | 1.143t/t |

| Acetaldehyde Yield | 99.7%wt |

Scan QR to Read

Links:https://www.globefindpro.com/products/22922.html

Links:https://www.globefindpro.com/products/22922.html

Recommended Products

-

Filter Press

Filter Press

-

Conveying Vibratory Feeder

Conveying Vibratory Feeder

-

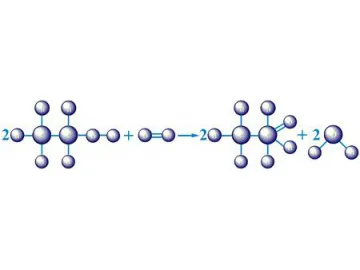

Vibrating Screen USL Series Linear Screen Machine

Vibrating Screen USL Series Linear Screen Machine

-

DMMn Plant

DMMn Plant

-

Vibrating Screen DYS Series Circular Motion Screen

Vibrating Screen DYS Series Circular Motion Screen

-

Paraformaldehyde Plant

Paraformaldehyde Plant

-

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

UF MUF Resin Glue Plant (Urea Formaldehyde and Melamine Urea Formaldehyde)

-

Spray Dryer Paraformaldehyde Plant

Spray Dryer Paraformaldehyde Plant

-

99.5% Concentration Methylal Plant

99.5% Concentration Methylal Plant

-

37%-42% Concentration Absorption Tower

37%-42% Concentration Absorption Tower

-

Liquid Phase Hexamine Plant

Liquid Phase Hexamine Plant

-

Roots Blower

Roots Blower

Hot Products