Robotic Pick and Pack Systems

The robotic pick and place system utilizes a visual control system, while the positioning arm utilizes a multi-axis motion system to carry out an incredibly fast and accurate pick and place process. The robotic pick and place system is capable of automatic picking, stacking, and sorting based on specific customer requirements.

Users can also equip the robotic product feeder with a check weigher, metal detector, conveyor systems and packing machines to build a complete production line with a much higher efficiency. The robotic pick and place product feeder is widely used in production lines for food, medicine, seasoning powders, plastics, crafts electrical parts, and more.

Vacuum (Suction) lifter

Pneumatic control parts

Handheld teach pendant

Mat top conveyor driven by servo

Technical parameters

| Model | JW-D1100 |

| Product Code | D1100-1-1 |

| Structure | DELTA (4-axis integrated in parallel connection) |

| Repetitive accuracy | ±0.01mm |

| Maximum speed (Pack/Min) | 150P/M |

| Arm working range | φ1100mm |

| Maximum product weight | 3000g |

| Power supply | 220V/4KW/ 50/60Hz |

| Machine dimension (L×W×H) | 1200×1100×610mm |

| Machine weight | 110Kg |

Scan QR to Read

Links:https://www.globefindpro.com/products/23025.html

Links:https://www.globefindpro.com/products/23025.html

Recommended Products

-

High Accuracy Checkweigher

High Accuracy Checkweigher

-

Stand-Up Product Metal Detector

Stand-Up Product Metal Detector

-

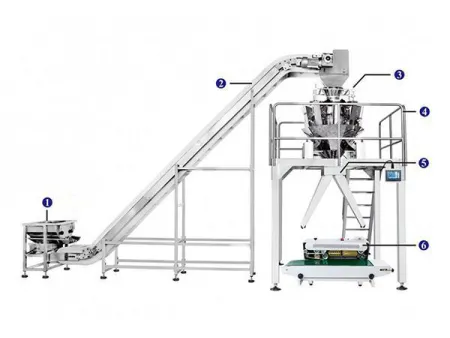

JW-LCX6 Automatic Vertical Form Fill and Seal Machine, with 10 or 14 heads weigher

JW-LCX6 Automatic Vertical Form Fill and Seal Machine, with 10 or 14 heads weigher

-

Vertical Form Fill Seal Machine (VFFS)

Vertical Form Fill Seal Machine (VFFS)

-

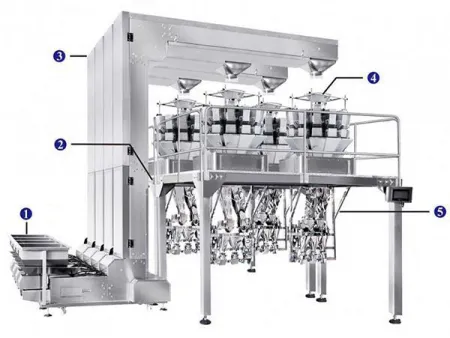

JW-LCX3 Form, Fill and Seal Bagging System,with 14 heads weigher

JW-LCX3 Form, Fill and Seal Bagging System,with 14 heads weigher

-

Metal Detector For Aluminum Foil Packaged Products

Metal Detector For Aluminum Foil Packaged Products

-

VFFS Machine for Large Bag Packaging,5-50kg,Inclined feeding conveyor

VFFS Machine for Large Bag Packaging,5-50kg,Inclined feeding conveyor

-

JW-BZD3 Semi-Automatic Packing Line,with 4 heads linear weigher

JW-BZD3 Semi-Automatic Packing Line,with 4 heads linear weigher

-

Semi-Automatic Packing Line (manual operation),with 14 heads weigher, Inclined feeding conveyor

Semi-Automatic Packing Line (manual operation),with 14 heads weigher, Inclined feeding conveyor

-

Rotary Collecting Table

Rotary Collecting Table

-

JW-BZD2 Semi-Automatic Packing Line,with 10 heads weigher

JW-BZD2 Semi-Automatic Packing Line,with 10 heads weigher

-

Cup Filling and Capping Line with Automatic Weighing System, 14 Head Weigher

Cup Filling and Capping Line with Automatic Weighing System, 14 Head Weigher