Vertical Form Fill Seal Machine (VFFS)

The vertical form fill seal machine is driven by a dual servo motor and is able to fully control acceleration, deceleration and positioning. The maximum production speed reaches 100 bags per minute. With a convenient operation, the vertical form fill seal machine has a standard configuration of stainless steel or carbon steel machine structure (selective assembly), vacuum pull bets for easier control on thin metallized films as well as a hinged electrical enclosure. Either side of the bagging machine is able to connect with other equipment.

Applicable packing products: All types of snacks, frozen foods, pet foods, puffed foods, medicinal materials, hardware and more

Applicable bag types: Pillow bags, gusset bags, euro slot bags and more

Applicable film materials: All types of composite films, single layer PE film

Applicable film thickness: 0.04mm-0.15mm

Advantages

Control: Uses a PLC control panel that allows for malfunction display, malfunction alerts, and a protective stop function whenever the door is opened.

Bag forming: Automatic vertical bag forming.

Bag filling and sealing: Both the vertical and horizontal sealer bar is driven by an air cylinder, and carries out bag sealing via a continuous heating. The vertical form fill seal machine can make sealed bags (the system will stop automatically if the sealing bars clamp on the products) or reopen bags with a sticker/clip.

Film tension: Driven by servo motor to adjust the tension on film transportation. This ensures the bag forming consistency.

Film transport & unwind: Uses an air-expansion of the mechanical film shaft, and is equipped with label printing adjustment, color code tracking adjustment, and auto alert without feeding.

Machine structures: Stainless steel or carbon steel structure (selective assembly).

Vertical form fill seal machine operation flow

① Film roll

② Film tightening

③ Label printing

④ Color code tracking

⑤ Forming

⑥ Edge sealing

⑦ Filling

⑧ Sealing jaws

⑨ Cutting

⑩ Bag discharging

Available Models

| Models | JW-E3220 | JW-E4230 | JW-E5235 | JW-E6240 | JW-E7245 | JW-E8350 | JW-H3220 | JW-H4230 | JW-H5235 | JW-H6240 | JW-H7245 | JW-H8350 |

| Applicable film width | 140-320mm | 160-420mm | 180-520mm | 180-620mm | 180-720mm | 180-830mm | 140~320mm | 160~420mm | 180~520mm | 180~620mm | 200~720mm | 180~830mm |

| Bag length range | 60-200mm | 60-300mm | 60-350mm | 80-400mm | 90-450mm | 90-500mm | 60-200mm | 60-300mm | 60-350mm | 80-400mm | 90-450mm | 60-500mm |

| Bag width range | 60-150mm | 70-200mm | 80-250mm | 80-300mm | 70-350mm | 60-400mm | 60-150mm | 70-200mm | 80-250mm | 80-300mm | 70-350mm | 80-400mm |

| Bagging speed | 15-70bags/min | 15-60bags/min | 15-60bags/min | 15-60bags/min | 0-70bags/min | 5-50bags/min | 15~100bags/min | 15~100bags/min | 15~90bags/min | 15~85bags/min | 0~70bags/min | 5~65bags/min |

| Power supply | 2.5KW/220/50/60HZ | 3.4KW/220V/50/60HZ | 3.4KW/220V/50/60HZ | 3.6KW/220V/50/60HZ | 5.5KW/220V/50/60HZ | 5KW/220V/50/60HZ | 2.9KW/220/50/60HZ | 4.5KW/220V/50/60HZ | 4.5KW/220V/50/60HZ | 5.1KW/220V/50/60HZ | 5.5KW/220V/50/60HZ | 6.5KW/220V/50/60HZ |

| Operation pressure | 0.6-0.8Mbra | 0.6-0.8Mbra | 0.6-0.8Mbra | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6~0.8Mbra | 0.6~0.8Mbra | 0.6~0.8Mbra | 0.6~0.8MPa | 0.6~0.8MPa | 0.6~0.8MPa |

| Gas consumption speed | 0.5m³/min | 0.6m³/min | 0.7m³/min | 0.8m³/min | 0.4m³/min | 1.2m³/min | 0.15m³/min | 0.2m³/min | 0.2m³/min | 0.2m³/min | 0.4m³/min | 0.4m³/min |

| Machine dimension (L×W×H) | 1158×930×1213mm | 1465×1040×1470mm | 1540×1160×1600mm | 1640×1226×1709mm | 1748×1344×1955mm | 1848×1544×2155mm | 1158×930×1213mm | 1400×1100×1560mm | 1514×1154×1590mm | 1640×1226×1709mm | 1748×1344×1955mm | 1848×1544×2155mm |

| Machine weight | 350Kg | 400Kg | 450Kg | 550Kg | 680Kg | 800Kg | 350Kg | 450Kg | 500Kg | 550Kg | 680Kg | 850Kg |

Selective assembly equipment

Gusset device

Gas flushing device (Nitrogen filling)

Chain-bag capability

Vibration device

Round or Euro hole punch

Custom sealing method

Air flushing system

Tear notch PE film sealing method

Bag support device

Static eliminator

Vacuum device

Horizontal-seal cooling system Automatic film alignment device

Feeding device

PLC RFID option for better security

Could connect with the following equipment

Multihead weigher

Linear weigher

Cup filler

Auger filler

Liquid pump

Links:https://www.globefindpro.com/products/23030.html

-

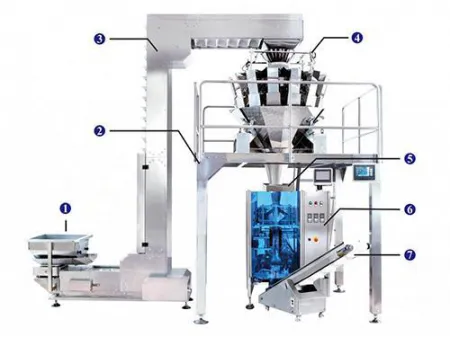

JW-LCX3 Form, Fill and Seal Bagging System,with 14 heads weigher

JW-LCX3 Form, Fill and Seal Bagging System,with 14 heads weigher

-

Metal Detector For Aluminum Foil Packaged Products

Metal Detector For Aluminum Foil Packaged Products

-

JW-LCX2 Twin Tube Vertical Bagging System,with 14 heads weigher, double discharge outlet

JW-LCX2 Twin Tube Vertical Bagging System,with 14 heads weigher, double discharge outlet

-

JW-C200 Check Weigher

JW-C200 Check Weigher

-

JW-LCX1 Vertical Form, Fill and Seal Line,with 12 heads weigher

JW-LCX1 Vertical Form, Fill and Seal Line,with 12 heads weigher

-

Working Platforms

Working Platforms

-

JW-LCX6 Automatic Vertical Form Fill and Seal Machine, with 10 or 14 heads weigher

JW-LCX6 Automatic Vertical Form Fill and Seal Machine, with 10 or 14 heads weigher

-

Stand-Up Product Metal Detector

Stand-Up Product Metal Detector

-

High Accuracy Checkweigher

High Accuracy Checkweigher

-

Robotic Pick and Pack Systems

Robotic Pick and Pack Systems

-

VFFS Machine for Large Bag Packaging,5-50kg,Inclined feeding conveyor

VFFS Machine for Large Bag Packaging,5-50kg,Inclined feeding conveyor

-

JW-BZD3 Semi-Automatic Packing Line,with 4 heads linear weigher

JW-BZD3 Semi-Automatic Packing Line,with 4 heads linear weigher