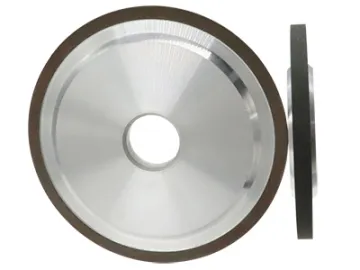

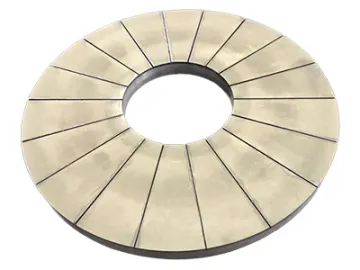

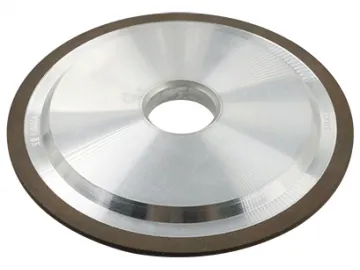

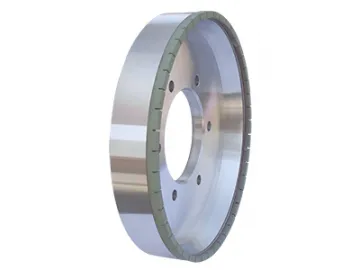

Semiconductor Mold Grinding Wheel, Resin Bond Grinding Tools

This product has been discontinued and removed from our shelves.

The grinding wheel and resin bond grinding tools are used for grinding semiconductors, such as light guide plates, electronic circuits, light guide glass, fibers and more. The semiconductor mold grinding wheel can be equipped on surface grinding equipment from a variety of brands, including Okamoto, Mitsui High-tec and Nagashima Seiko, and all feature an excellent polishing performance. The sharpness also ensures there will be no machine blockage during grinding.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) |

| 12 | 8-12 | 6 | 2/3 |

| 14 | 8-14 | ||

| 15 | |||

| 16 | 8-16 | 10 | |

| 18 | |||

| 20 | |||

| 23 | 12-20 | ||

| 25 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 |

| 30 | 5/6/8/10/12/13 | ||

| 35 | 10/12/12.7/16 | 2/2.5/3/4/5 | |

| 40 | 0.2-20 | 8/10/12/12.7/16 | |

| 45 | |||

| 50 | |||

| 60 | 8/10/12/12.7/16/19.05/20/22.23 | ||

| 75 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 |

| 80 | |||

| 100 | 0.4-35 | 20/22.23/25.4/31.75/32 | 3-6 |

| 115 | 2-20 | 20/22.23/25.4/31.75/32 | |

| 125 | 0.8-35 | 4/5/6/8/10 | |

| 150 | 1-35 | 25.4/31.75/32/40 | |

| 175 | 3-35 | 31.75/32/40 | 5/6/8/10/16 |

| 180 | 10-40 | 31.75/32/40/50.8/75/76.2 | |

| 200 | 1-40 | 5/6/8/10/16/20 | |

| 250 | 10-60 | 50.8/75/76.2/101.6/127 | |

| 300 | 3-60 | 75/76.2/101.6/127/203 | 5/6/8/10/16/20/25 |

| 350 | 12-50 | 127/203 | |

| 400 | 3.5-50 | ||

| 450 | 12-60 | 203/304.8/305 | 5/6/8/10/12/15 |

| 500 | |||

| 600 | |||

| 700 | |||

| 750 | |||

| 800 | 18-50 | 132/304.8/305 | |

| 850 | |||

| 900 | |||

| Note: other specifications can be customized upon request! | |||

14A1 Grinding wheel

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) |

| 75 | 5-10 | 19.05/20 | 40-50 | 0.8-5 | 2-5 |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 |

| 125 | 90-110 | ||||

| 150 | 10-15 | 31.75/32 | 100-130 | 1-10 | |

| 175 | 12-20 | 120-140 | |||

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 |

| 250 | 150-200 | 5-10 | |||

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | 4/5/6/8/10 |

| 350 | 250-300 | ||||

| 400 | 20-50 | 300-350 | 6-20 | 5/6/8/10/12/15 | |

| 500 | 203/305 | 350-400 | 10-30 | ||

| 600 | 20-60 | 305 | 400-500 | ||

| 700 | 450-600 | ||||

| Note: other specifications can be customized upon request! | |||||

Scan QR to Read

Links:https://www.globefindpro.com/products/23256.html

Links:https://www.globefindpro.com/products/23256.html

Recommended Products

-

Resin Bond Grinding Wheel for Wood Cutting

Resin Bond Grinding Wheel for Wood Cutting

-

Peripheral grinding wheel

Peripheral grinding wheel

-

Resin Bond Grinding Wheel

Resin Bond Grinding Wheel

-

Resin Bonded Grinding Wheel

Resin Bonded Grinding Wheel

-

Taper cup Resin Grinding Wheel

Taper cup Resin Grinding Wheel

-

Resin Wheel for Grinding Light Fixture

Resin Wheel for Grinding Light Fixture

-

Both Side Coated Vitrified Diamond Grinding Wheel

Both Side Coated Vitrified Diamond Grinding Wheel

-

3A1 Grinding Wheel

3A1 Grinding Wheel

-

Resin Bond Diamond Wheels for Dressing PCB Drill Bits

Resin Bond Diamond Wheels for Dressing PCB Drill Bits

-

Resin Bond Diamond Grinding Wheel for Tungsten Carbide Tool

Resin Bond Diamond Grinding Wheel for Tungsten Carbide Tool

-

Vitrified bond Grinding Wheel for Polycrystalline silicon

Vitrified bond Grinding Wheel for Polycrystalline silicon

-

3F1 Grinding Wheel

3F1 Grinding Wheel

Hot Products