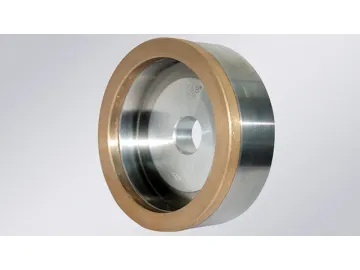

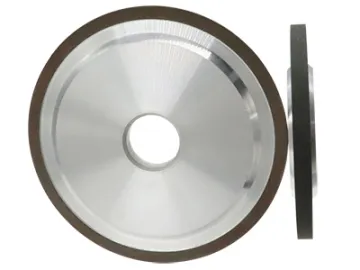

Resin Wheel for Grinding Light Fixture

This product has been discontinued and removed from our shelves.

This resin wheel is available as either a diamond type or CBN type, and is capable of polishing workpieces into a mirror finish. It is used for light guide plates, LED bulb shells, and other photic and electrical products.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) |

| 12 | 8-12 | 6 | 2/3 |

| 14 | 8-14 | ||

| 15 | |||

| 16 | 8-16 | 10 | |

| 18 | |||

| 20 | |||

| 23 | 12-20 | ||

| 25 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 |

| 30 | 5/6/8/10/12/13 | ||

| 35 | 10/12/12.7/16 | 2/2.5/3/4/5 | |

| 40 | 0.2-20 | 8/10/12/12.7/16 | |

| 45 | |||

| 50 | |||

| 60 | 8/10/12/12.7/16/19.05/20/22.23 | ||

| 75 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 |

| 80 | |||

| 100 | 0.4-35 | 20/22.23/25.4/31.75/32 | 3-6 |

| 115 | 2-20 | 20/22.23/25.4/31.75/32 | |

| 125 | 0.8-35 | 4/5/6/8/10 | |

| 150 | 1-35 | 25.4/31.75/32/40 | |

| 175 | 3-35 | 31.75/32/40 | 5/6/8/10/16 |

| 180 | 10-40 | 31.75/32/40/50.8/75/76.2 | |

| 200 | 1-40 | 5/6/8/10/16/20 | |

| 250 | 10-60 | 50.8/75/76.2/101.6/127 | |

| 300 | 3-60 | 75/76.2/101.6/127/203 | 5/6/8/10/16/20/25 |

| 350 | 12-50 | 127/203 | |

| 400 | 3.5-50 | ||

| 450 | 12-60 | 203/304.8/305 | 5/6/8/10/12/15 |

| 500 | |||

| 600 | |||

| 700 | |||

| 750 | |||

| 800 | 18-50 | 132/304.8/305 | |

| 850 | |||

| 900 | |||

| Note: other specifications can be customized upon request! | |||

14A1 Grinding wheel

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) |

| 75 | 5-10 | 19.05/*20 | 40-50 | 0.8-5 | 2-5 |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 |

| 125 | 90-110 | ||||

| 150 | 10-15 | 31.75/32 | 100-130 | 1-10 | |

| 175 | 12-20 | 120-140 | |||

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 |

| 250 | 150-200 | 5-10 | |||

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | |

| 350 | 250-300 | ||||

| 400 | 20-50 | 300-350 | 6-20 | 5/6/8/10/12/15 | |

| 500 | 203/305 | 350-400 | 10-30 | ||

| 600 | 20-60 | 305 | 400-500 | ||

| 700 | 450-600 | ||||

| Note: other specifications can be customized upon request! | |||||

Scan QR to Read

Links:https://www.globefindpro.com/products/23262.html

Links:https://www.globefindpro.com/products/23262.html

Recommended Products

-

Internal Grinding Wheels, Vitrified Bonded Wheel

Internal Grinding Wheels, Vitrified Bonded Wheel

-

Resin Grinding Wheel for Paper Cutting Tools

Resin Grinding Wheel for Paper Cutting Tools

-

Metal Bond Grinding Wheel

Metal Bond Grinding Wheel

-

1A1 Grinding Wheel

1A1 Grinding Wheel

-

1A8 Grinding Wheel

1A8 Grinding Wheel

-

TJ350 Copper Bus Bar & Profile Line

TJ350 Copper Bus Bar & Profile Line

-

Taper cup Resin Grinding Wheel

Taper cup Resin Grinding Wheel

-

Resin Bonded Grinding Wheel

Resin Bonded Grinding Wheel

-

Resin Bond Grinding Wheel

Resin Bond Grinding Wheel

-

Peripheral grinding wheel

Peripheral grinding wheel

-

Resin Bond Grinding Wheel for Wood Cutting

Resin Bond Grinding Wheel for Wood Cutting

-

Semiconductor Mold Grinding Wheel, Resin Bond Grinding Tools

Semiconductor Mold Grinding Wheel, Resin Bond Grinding Tools