Design ability

RAP SEV could provide different customization solution including vehicle color, logo, multiple layer structure of container, and rear parts types to meet the requirement of customers.

Why choose RAP SEV?The technical team of RAP SEV is composed of professionals with rich experience in vehicle design and production. The technical director, the minister of project management and minister of technology have been engaged in automobile research for 18 years, 12 years and 12 years respectively. Also, each project engineer has over 7 years of experience in automobile design and development.

Additionally, the software used in the design process includes CATIA, UG, 3Dmax, Alias, pro/E, CAXACAD, 3D fluid simulation and analysis software, vehicle dynamics simulation system, fatigue analysis software and so on.

RAP SEV started the design and development of Bange and OAK series electric 3 wheelers in 2006, and the work result has been fully delivered at present.

Design schemeIn the design process, the sketches and renderings will have been modified many times. RAP SEV focuses on the design philosophy and the shape of the vehicle is a “G” which means green. Also, “G” means global and green messenger.

The headlights of the vehicle are a combination of two triangles like an hourglass, the two “V” means the voyage of time.

Plastocene model Model makingPlastocene modelling helps designers work out the scale, lines, and other characteristics of the vehicle. Also, it has strong plasticity to help design adjust the model and improve the design.Model reviewAfter making the model, each department of RAP SEV will evaluate the appearance of the model and adjust it according to the suggestions to make it in real form in the finally.

The main focus in the early stage of the project is the design of whole layout including man-vehicle size, global key parameters, driver visual field check and so on.

Frame

Generally, the frame is made by high strength carbon steel to withstand the impact and vibration from the road in long time driving. The front part and the rear part are split to ensure flexibly turn. We can also customize a lighter aluminum alloy frame according to the requirements of the customer, which is made by the combination of welding and riveting to ensure its strength and easy assembly.

Traditional frame Improved frame The swinger

The swinger is one of the core components for 3 wheelers since it is a type of swing vehicle.

A. Long-span double bearing design to carry large loads with high rigidity and small deformation.

B. Can be converted between electric locking and manual locking by only changing the internal components.

C. Less locking parts, controllable clearance, longer service life and higher reliability.

Double handlebar

In order to facilitate vehicle parking and swing lock, RAP SEV set the swing lock and parking lock control mechanism on the handlebar, and strengthen the safety of passengers under the open state of the mechanism.

Basalt fiber wind scooper

The vehicle roof frame adopts the new inorganic, environment-friendly and high-performance basalt fiber material to ensure the high strength of the frame and electrical insulation, corrosion resistance, high temperature resistance.

Damper

In order to increase the stability of the vehicle with large load, RAP SEV increase the proportion of the front axle load and adopt the anti-shake damper to effectively inhibited the handlebar rock during high-speed braking caused by excessive torque of front wheel drag. Besides, the design can also reduce the vibration of the driver due to the rough road.

Torsion beam independent suspension

Connect the front part of the torsion beam semi-independent suspension system with the vehicle by elastic rotation to have the advantages both of independent suspension and non-independent suspension, balance the fluctuation of the left and right wheels, and improve the stability and comfort of the vehicle.

Adjustable backrest

In order to meet the driving comfort of different people, both Bange series and OAK series 3 wheelers are designed with two different adjustable backrests, internal and external. The structure is simple and reasonable, can realize stepless adjustment without removing any parts.

Large volume container

Storage volume is very important for fast logistics transportation. Focusing on express delivery, the Bange series 3 wheelers have a capacity of 1400L to meet the requirements of bulk express delivery. While for catering, the OAK series 3 wheeler also has a capacity of 450L, and has heating and cooling zones to meet the storage and delivery requirements of special products such as seafood and cold drinks.

Data analysis

In the overall frame construction stage, RAP SEV carry on the finite element analysis for the frame, wind scooper bracket, handlebar and other core components to ensure that the vehicle has enough strength and rigidity and the frame could fully meet the requirement of the lightweight vehicle under various working conditions and road types.

In the plastocene making and engineering design stage, RAP SEV carries out the aerodynamic simulation analysis and adjust the surface of the vehicle to reduce wind resistance and noise, so as to increase driving distance.

Vehicle trial production process

RAP SEV has great production conditions and a high-quality professional manufacturing team including more than 20 technical experts and senior managers with over 20 years of experience in the automotive industry. The staff in the workshop are all graduates with automotive, mechanical or associated majors.

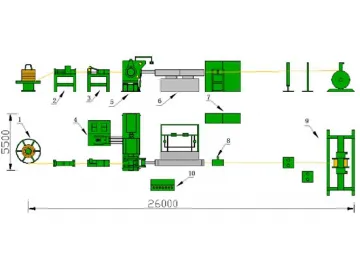

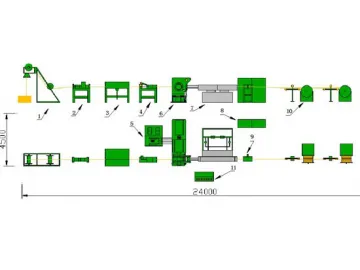

We also have high-quality production equipment including an assembly automation line, KBK crane, refueling machine, air compressor, etc. The assembly automation line is used to deliver products to the next post automatically. The KBK crane is used to lift the frame and other chassis parts and to the corresponding post. The refueling machine is used to ensure the braking performance of the vehicles by refueling. The air compressor is used with all equipment in the assembly line.

Receiving inspection

Testing item: mechanical testing of material properties.

Testing equipment: Rockwell apparatus, Shore durometer, tension meter, etc.

Testing purpose: to ensure that the mechanical properties of parts meet the design requirements.

Process inspection

Test item: sealing properties of braking system.

Test equipment: vacuum filling device of brake fluid.

Test purpose: to ensure that the sealing properties of braking system meet the requirements

Whole vehicle inspection

Test items: vehicle safety performance including speedometer, axle weight test, braking performance, light performance, horn sound level.

Testing equipment: vehicle safety performance test line.

Test purpose: to ensure the safety of the vehicle meets the requirements.

Road testing is an effective way to confirm the reliability and road suitability of vehicles. RAP SEV has a special motorcycle test site to carry out the vehicle test with various road conditions. The vehicle has passed all test items on the 6000km and got effective adjustment and improvement. Besides, the rectification work of 3S vehicle is also coming to an end.

Road condition: flat section, climbing section, bumpy section, twisted section.

Links:https://www.globefindpro.com/products/23299.html

-

Precision Sprockets

Precision Sprockets

-

TJ550 Copper Bus Bar & Profile Line

TJ550 Copper Bus Bar & Profile Line

-

Speed Reducer Gear

Speed Reducer Gear

-

LJ350B Al Flat Wire & Sector Line

LJ350B Al Flat Wire & Sector Line

-

2 Seater Electric Three Wheeler

2 Seater Electric Three Wheeler

-

3 Wheel Electric Cargo Scooter, OAK Series, L2e-U

3 Wheel Electric Cargo Scooter, OAK Series, L2e-U

-

Three Wheeler Cargo Truck

Three Wheeler Cargo Truck

-

TJ600 Copper Bus Bar & Profile Line

TJ600 Copper Bus Bar & Profile Line

-

Electroplated Grinding Wheel

Electroplated Grinding Wheel

-

2A2 Grinding Wheel

2A2 Grinding Wheel

-

1V1 Grinding Wheel

1V1 Grinding Wheel

-

Taper cup Grinding wheel

Taper cup Grinding wheel