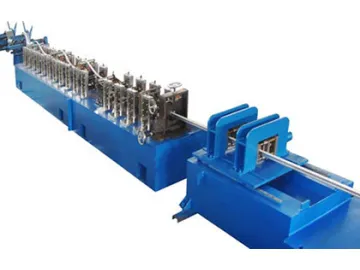

Garage Door Roll Forming Line

This garage door roll forming line is a continuous PU sandwich panel line that produces double-skinned sectional door panels with polyurethane insulated core. This garage door production line mainly consists of uncoiler, leveler, upper and lower roll formers, PU foam injection machine, hydraulic press, fly saw cutting system.

Samples of Finished Product Production ProcessIn the sandwich panel production process, PU foam is continuously sprayed under high pressure into upper and lower sheet metal profiles that are formed by upper and lower roll forming machines respectively. The PU insulated sandwich panel is then cut off to desired length via fly cutting saw prior to being discharged and collected.

Features Quick change system of roll forming machine enables forming rolls to be quickly and easily changed for producing different profiles. PLC control system adopts imported motion controller to guarantee high precision, and drive system utilizes only Siemens servo motors. The roll forming line is designed with gear transmission system, ensuring that the machine has high precision and long lifespan. Fly saw cutting system adopts hydraulic cutting method. Components of Garage Door Roll Forming Line Uncoiler Loading capacity: 5 tons Coil outer diameter: 1,100mm Coil inner diameter: 480-510mm Plate width: 1250mm Drive power: 5.5kW Hydraulic power automatic expansion to tighten the coil Hydraulic power (automatic coil tensioning): 5.5kW Embossing Machine Max. width of embossing pattern (normally wood grain pattern): 850mm Footprint size (D×W×H): 1770×3087×1500mm Motor power: 5.5kW, 50HZ/60HZ, 220V/380V Panasonic speed control (in freestanding cabinet): 8-15m/min Embossing roller size: Ø340×1000 Rubber drive rollers at feed station Pattern matches the thickness of the sample provided Runout table rollers are mounted on a main frame of 500mm Levelling and Feeding Machine The leveler adopts leveling rollers for precision leveling of sheet metal The feeding section is driven by servo motor, and uses rubber rollers for feeding Gear transmission method Motor power: 1.5kW Hydraulic Press (200/300Ton) Nominal pressure: 2000kN/3150kN Master cylinder stroke: 400mm Cylinder pressure: 1000kN/630kN Cylinder stroke: 100mm Max. opening (daylight): 500mm Working area: 1200mm×1300mm / 950mm×950mm Motor power: 15kW/22kW Hydraulic motor: 15kW/22kW, 220V/380V, 50HZ/60HZ, 3 Phases, Siemens brand Hydraulic pump: Yuken brand Taiwan Hydraulic valve: Rexroth Germany Hydraulic cylinder: China Upper Roll Forming Machine Forming stations: 18 stations, cast steel structure Forming rolls: CR15 steel, HRC60 hardness, chrome coated (0.03-0.05mm), strength of 800Mpa Shaft: 60mm diameter, #45 steel, quenching hot treatment, main shaft strength of 650Mpa Bearing brand: FAG Germany Main motor: 7.5kW×2 (two motors), 220V/380V, 50HZ/60HZ, 3 Phases (Siemens brand) Gear transmission system Automatic width adjustment with servo control Final product width: 300-620mm Final product thickness: 40-55mm Applicable material: color coated steel sheet of 0.45 to 0.65mm in thickness Lower Roll Forming Machine Forming stations: 25 stations, cast steel structure Forming rolls: CR15 steel, HRC60 hardness, chrome coated (0.03-0.05mm), strength of 800Mpa Shaft: 60mm diameter, #45 steel, quenching hot treatment, main shaft strength of 650Mpa Bearing brand: FAG Germany Main motor: 7.5kW×2 (two motors), 220V/380V, 50HZ/60HZ, 3 Phases (Siemens brand) Gear transmission system Automatic width adjustment with servo control Final product width: 300-620mm Final product thickness: 38-76mm Applicable material: color coated steel sheet of 0.45 to 0.65mm in thickness Double Bridge Device and Conveyor Conveyor type: roller conveyor Roller diameter: Ø60 Roller length: 1200mm Conveyor frame: channel steel and steel plate Heating and Pre-heating SystemThis system is used to maintain a precise and uniform temperature of the upper and lower facing layers, thus achieving a homogeneous foam reaction as well as an excellent bonding between foam and facing layer.

Welded steel base frame features protection grille which is lockable and thermally insulated Adjustable roller bars support the upper and lower formed sheet Top and bottom supports hold the infrared modules Infrared modules have heater steel sheet hoods to contain infrared heater tubes and fans Twin-tube quartz glass infrared heater, gold-plated PLC temperature control PLC Control Cabinet Touch screen brand: Delta PLC brand: Siemens Inverter brand: Siemens Low-voltage electrical components brand: Schneider Germany Encoder brand: Omron Sensor brand: Balluff B F Control motion/production process: ①Uncoiler→Embossing Machine→Upper Roll Forming Machine→Pre-heating System→High Pressure PU Foaming Machine→Double Belt System (Continuous Press) and Side Block Feeding Machine and Heating System (for Double Belt)→Scanning Machine→Fly Saw Cutting System→Automatic Runout Table

②Uncoiler→Embossing Machine→Servo Driven Automatic Feeding System→200Ton Hydraulic Press →300Ton Hydraulic Press →Preheating System→High Pressure PU Foaming Machine→Double Belt System (Continuous Press) and Side Block Feeding Machine and Heating System (for Double Belt)→Scanning Machine→Fly Saw Cutting System→Automatic Runout Table

The polyurethane foaming machine has pump for polyurethane and isocyanate, adjustable to double length and line speed

Foam pressure: 220bar (max.)/ 60bar (min.) Max. viscosity: 3.000mPas Double Belt System (Continuous Press) Length of double belt system: 18m Working height of lower belt: 1300mm Slat width: 900mm (upper)/900mm(lower) Number of slats per belt: 260 Number of hydraulic cylinders: 6 pairs Lifting stroke of upper belt: max. 380mm Foaming pressure: max. 0.4bar Lifting time of upper belt: approx. 2min Power required for A.C. drive: approx. 2×12kW Power required for hydraulic unit: approx. 7.5kW Oil reservoir: approx. 160L Mechanical speed: 2m/min-12m/min Heating System for Double Belt Slat temperature: max. 60°C Temperature accuracy: ± 3°C Ambient temperature for production: 15°C to 35°C U-value of housing: 1W/m²K Heat-up time from 20°C to 40°C: approx. 2 hours Circulating air volume: approx. 2×8000m3/h Required heating power: 2×80kW Required hot water circuit pump:2×6.5m³/h Required hot water in-feed temperature: 110°C Required hot water return temperature: 90°C Fly Saw Cutting SystemTwin diagonal cross cutting saw is provided to cut the panel with two saw blades.

Working height: 1300mm Length: 3000mm Width: 2500mm Panel width: max.650mm Diameter of saw blade: 500mm Drive speed: 700-1.500rpm Cutting accuracy: ±2mmHuazhong is committed to the innovation of roll forming machines and helping customers lower their costs and stay ahead in their competitive market.

Tags: coil processing equipmentpanel roll former

coil processing lines

lines for sandwich panels

coil straightener

Links:https://www.globefindpro.com/products/2458.html

-

Curved Roof Roll Forming Machine

Curved Roof Roll Forming Machine

-

Label Finishing Machine

Label Finishing Machine

-

Stud and Track Roll Forming Machine

Stud and Track Roll Forming Machine

-

Flatbed Die Cutting Machine, Dragon-330

Flatbed Die Cutting Machine, Dragon-330

-

Heavy Equipment Turbochargers, Replacement Turbos for Construction Equipment

Heavy Equipment Turbochargers, Replacement Turbos for Construction Equipment

-

39/42/55 Roller Shutter Slat Roll Forming Line

39/42/55 Roller Shutter Slat Roll Forming Line

-

Roller Shutter Garage Door Roll Forming Line

Roller Shutter Garage Door Roll Forming Line

-

C/Z Purlin Roll Forming Machine

C/Z Purlin Roll Forming Machine

-

Rotary Label Die Cutting Machine, FQ-330R/450R

Rotary Label Die Cutting Machine, FQ-330R/450R

-

Flatbed Die Cutting Machine, MQ-350

Flatbed Die Cutting Machine, MQ-350

-

Deck Roll Forming Machine

Deck Roll Forming Machine

-

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine