Flatbed Die Cutting Machine, Dragon-330

ZONTEN Machinery independently researched and developed patented die-cutting machines. With the label market price moving towards the era of meager profit and higher and higher labor costs, the flat bed high speed die cutting machine was developed. This die cutter adopts a dancer paper feeding system with a maximum speed of 120m/min (400 times/min). Except for the intermittent movement of the paper feeding in the die-cutting part, the paper is fed at a constant speed.

The Dragon-330 flat bed high speed die cutting machine is also equipped with a hot stamping unit fully controlled by a servo driver, and the stamping unit is electrically heated. Servo-controlled intermittent foil tape rewinding and unwinding can ensure die-cutting speed of 120 m/min, and support 90-degree rapid rotation. The foil tape rewinding and unwinding unit adopts a differential air shaft with slipping friction, which can feed multiple foil tapes with different roll diameters on a single shaft at the same time, and can hold a maximum of 3000m foil tape. This greatly improves efficiency. More and more customers use flat bed high speed die cutting machine to replace the previous low speed die cutter.

| Model | Dragon -330 |

| Max. web width | 330mm |

| Max. unwinding diameter | 700mm |

| Max. rewinding diameter | 700mm |

| Registration | Sensor |

| Die cutting & hot stamping size | 320*350mm |

| Die cutting speed | 400rpm/min, 120m/minute |

| Air supply | 0.4-0.6pa |

| Overall dimensions | 5650x1510x1820mm |

| Machine weight | 8000kg |

Unwinder with closed-loop tension control, electronic web guide with ultrasonic edge guide sensor Hot stamping unit

Horizontal/vertical 90° rotating and adjustable stamping. The sliding axis controls the material, and multiple rolls of material can be stamped at the same time. Snowball waste collection

Very good solution for handling defective labels after die cutting. Die cutting operation won’t stop during waste collection process. Slitting unit designed with double rewinder, and ten circular knives with minimum slit width of 17mm. Italy’s color tracking sensor to monitor black marks. Sheet feeding controlled by the servo driver, and the sheet length controlled by the PLC system Main electrical parts imported from internationally well-known brands, including Panasonic servo motor & driver, Trio UK PLC. Rotary flexo unit

Supports semi rotary & fully rotary operation controlled by the servo driver; 152Z printing cylinder equipped; comes with plates in thickness of 1,14 and1.7mm; used for 0.38 mm adhesive tapes. Silk screen printing unit

Links:https://www.globefindpro.com/products/2462.html

-

Heavy Equipment Turbochargers, Replacement Turbos for Construction Equipment

Heavy Equipment Turbochargers, Replacement Turbos for Construction Equipment

-

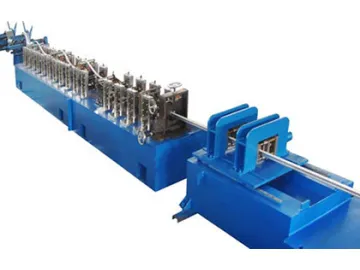

39/42/55 Roller Shutter Slat Roll Forming Line

39/42/55 Roller Shutter Slat Roll Forming Line

-

Conductive Adhesive Film, MZ-9705D

Conductive Adhesive Film, MZ-9705D

-

Aluminum Foil EMI Shielding Tape, MZ-9773AL

Aluminum Foil EMI Shielding Tape, MZ-9773AL

-

Flatbed Screen Printing Machine, SW-320

Flatbed Screen Printing Machine, SW-320

-

Double Sided Tapes

Double Sided Tapes

-

Stud and Track Roll Forming Machine

Stud and Track Roll Forming Machine

-

Label Finishing Machine

Label Finishing Machine

-

Curved Roof Roll Forming Machine

Curved Roof Roll Forming Machine

-

Garage Door Roll Forming Line

Garage Door Roll Forming Line

-

Roller Shutter Garage Door Roll Forming Line

Roller Shutter Garage Door Roll Forming Line

-

C/Z Purlin Roll Forming Machine

C/Z Purlin Roll Forming Machine