UV Curing Conveyor System

Other than LED light source, the conveying method is also important and C SAIL provides following conveying methods according to specific requirements.

Edge-Carry UV Curing Conveyor:

This conveying method is suitable for fast drying of electronic parts bonding, surface coating and printing and etc., because the processing products are transported along the rails and allows multi-direction curing on the products as well as excellent drying results.

Side-Cure Conveyor Systems:

Cure UV Adhesives and Coatings from the left, right, and/or top

Mesh Belt Conveyor Systems:

Mesh belt conveyor system is used in continuous mesh belt furnaces, this type of conveyor belt is able to function normally under extremely high-temperature environment with maximum of 1100°C. Continuous mesh belt furnaces could be used for various hot processing such as hardening, annealing, tempering, stress relieving and etc.

Other than the listed conveying methods, C SAIL also provides conveyor ovens & furnaces with different transportation methods such as flat belt style, chain conveyors, serpentine belt and etc.

The following shows some of our previously made custom industrial drying ovens/furnaces, please click the link below if you want to learn further more information.

UVA-201 UV Curing Conveyor System

UVA-202 UV Curing Conveyor Equipment

UVA-364 UV Curing Conveyor Equipment

UVA-842 UV Curing Conveyor Equipment

Edge-Carry UV Curing Conveyor:

This conveying method is suitable for fast drying of electronic parts bonding, surface coating and printing and etc., because the processing products are transported along the rails and allows multi-direction curing on the products as well as excellent drying results.

Side-Cure Conveyor Systems:

Cure UV Adhesives and Coatings from the left, right, and/or top

Mesh Belt Conveyor Systems:

Mesh belt conveyor system is used in continuous mesh belt furnaces, this type of conveyor belt is able to function normally under extremely high-temperature environment with maximum of 1100°C. Continuous mesh belt furnaces could be used for various hot processing such as hardening, annealing, tempering, stress relieving and etc.

Other than the listed conveying methods, C SAIL also provides conveyor ovens & furnaces with different transportation methods such as flat belt style, chain conveyors, serpentine belt and etc.

The following shows some of our previously made custom industrial drying ovens/furnaces, please click the link below if you want to learn further more information.

| Model | UVA-201 | UVA-202 | UVA-301 | UVA-362 | UVA-364 | UVA-482 | UVA-503 | UVA-752 | UVA-842 |

| Power | 220V 1Ø 50Hz | 380V 3Ø 50Hz | |||||||

| Light power (kW) | 2kW×1PCS | 2kW×2PCS | 3kW×1PCS | 3.6kW×2PCS | 3.6kW×4PCS | 4.8kW×2PCS | 5kW×3PCS | 7.5kW×2PCS | 8.4kW×2PCS |

| LED illumination intensity(W/C㎡) | 80 | 80/120 | |||||||

| Cooling method | Forced air cooling | ||||||||

| Effective illumination width | 250 | 250 | 375 | 300 | 300 | 400 | 420 | 625 | 700 |

| Remark | Illumination intensity is between 120~200 W/CM2, customizing at your desire. | ||||||||

UVA-201 UV Curing Conveyor System

UVA-202 UV Curing Conveyor Equipment

UVA-364 UV Curing Conveyor Equipment

UVA-842 UV Curing Conveyor Equipment

Scan QR to Read

Links:https://www.globefindpro.com/products/25066.html

Links:https://www.globefindpro.com/products/25066.html

Recommended Products

-

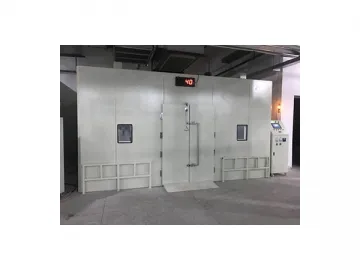

Continuous Conveyor Oven

Continuous Conveyor Oven

-

Eco-friendly Optical Mirror

Eco-friendly Optical Mirror

-

Microwave Tunnel Oven

Microwave Tunnel Oven

-

Mini UV Laboratory Curing Machine

Mini UV Laboratory Curing Machine

-

UV Curing for lable printing

UV Curing for lable printing

-

600°C Vacuum Oven

600°C Vacuum Oven

-

Heat Pump Drying System

Heat Pump Drying System

-

-

Linear Actuators & Electric Motion Control Products Manufacturer

Linear Actuators & Electric Motion Control Products Manufacturer

-

The ITO coated glass is separated by compartment paper or plastic compartments to effectively prevent damage to the glass and coating caused by sliding and friction. The ITO coated glass uses vacuum

The ITO coated glass is separated by compartment paper or plastic compartments to effectively prevent damage to the glass and coating caused by sliding and friction. The ITO coated glass uses vacuum

-

Plane Glass Optical Mirror

Plane Glass Optical Mirror

-

Coating Service

Coating Service