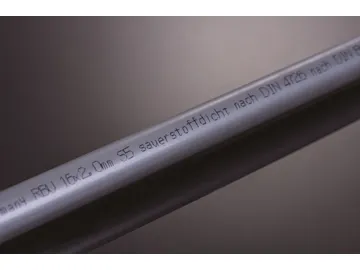

PEX-AL-PEX Pipe

The PEX-AL-PEX pipe is a composite pipe made of aluminum pipe, with the aluminum layer pressed between inner and outer layers of pipe. It combines the strength of a metal pipe with the durability of plastic. It can withstand temperatures up to as high as 95°C and a working pressure of 1.25MPa, thus meeting design requirements for high temperature radiation heating.

The PEX-AL-PEX pipe is widely used in drinking water systems, centralized water supply systems, radiator systems, heating systems, cooling systems and more.

Size selection of the PEX-AL-PEX pipe

Diameter: 3/8",1/2",5/8",3/4" and 1"

Wall thickness: 2mm

Material: PEX-AL-PEX, both the inner and outer layer cross-linked

AL layer thickness: 0.2 mm

Maximum working pressure: 10 bar (PN 10)

Maximum operating temperature: 95°C

Features of the PEX-AL-PEX pipe

The outer and inner layers of the PEX-AL-PEX pipe are made of PEX (silane crosslinking polyethylene)

The intermediate aluminum layer reinforces the structure of the pipe, thus forming and retaining a particular pipe shape.

It can withstand temperatures up to as high as 95°C and a working pressure of 1.25MPa, thus meeting design requirements for high temperature radiation heating.

The PEX-AL-PEX tube has a large aluminum layer that allows it to bear high loads. It has all the characteristics of a metal pipe, making it safe and reliable.

The thickness of the aluminum layer is evenly distributed, and the its stiffness is uniform. The hoop stress and shape change evenly, thus ensuring a reliable connection between the pipe and pipe fittings.

The product features smooth end, uniform pipe wall and excellent roundness.

Installation method of the PEX-AL-PEX pipe

Step 1: Place the pipe cutter vertically on the pipe for a smooth, clean cutting. The cut pipe should be free of burrs.

Step 2: Select the appropriate reamer guide size and insert it completely into the PEX-AL-PEX pipe. The edge of the pipe must come into contact with the reamer blade. While holding the pipe, push the reamer in and rotate it in 2-3 circles (in any direction). If the chip is being cut, it indicates that the program is being correctly carried out.

Step 3: Slide the compression nut over the pipe and insert the main body of the PEX-AL-PEX compression joint completely into the pipe

Step 4: Slide the nut and O ring into the joint direction by hand, and then hand-tighten the compression nut (about 2 circles) on the joint. Place a hook wrench on the connector and place another wrench on the compression nut, and then tighten the compression nut (about 1-1.5 circles).

Step 5: The connection is completed and then check the fittings.

Links:https://www.globefindpro.com/products/25190.html

-

PEX Pipe

PEX Pipe

-

Professional solution provider of sewage treatment

Professional solution provider of sewage treatment

-

Wireless Ceiling Mount LED Lamp, Item SC-H101C LED Lighting

Wireless Ceiling Mount LED Lamp, Item SC-H101C LED Lighting

-

Remote Control LED Ceiling Light, Item SC-H101A Indoor LED Lighting

Remote Control LED Ceiling Light, Item SC-H101A Indoor LED Lighting

-

PPR Pipe Fittings

PPR Pipe Fittings

-

Professional solution provider of sewage treatment

Professional solution provider of sewage treatment

-

Professional solution provider of sewage treatment

Professional solution provider of sewage treatment

-

PE-RT Pipe

PE-RT Pipe

-

Professional solution provider of sewage treatment

Professional solution provider of sewage treatment

-

Professional solution provider of sewage treatment

Professional solution provider of sewage treatment

-

IVORY WOOD Series Porcelain Tile

IVORY WOOD Series Porcelain Tile

-

Ales Series Glazed Porcelain Tile

Ales Series Glazed Porcelain Tile