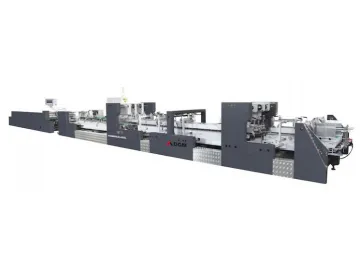

High Speed Carton Folding Gluing Line 2800 type Carton Folding Machine

High Speed Carton Equipment Manufacturer

Application

Application

B: 100 - 1300 mm crash-lock bottom box A: 650 - 2800 mm

B: max. 1300 mm

C: min. 120 mm

D: 40 - 200 mm 2-pieces box A: min. 550 mm

B: 100 - 1300 mm Processed materials Carton board Corrugated board Parameters

Processed materials

Capacity

Size and Weights

Installation

folding and gluing system components

Feeder section Splice section Lock bottom section Lower gluing unit Folding and closing section Trombone section Press section

Description

The high speed carton folding gluing line’s 2800 type carton folding machine has a maximum blank width of up to1350mm. The standard configuration has two lower gluing units and two upper electronic gluing systems.

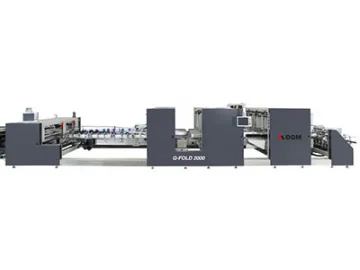

This series two-piece folding and gluing system has a feeder driven by an independent motor for handling either one sheet or two sheets. It accurately splices the two pieces of carton with the help of the lateral squaring device. It is ideal for the packaging of three-layer or five-layer large corrugated boards.

The G-FOLD 2800-AC without pre-folding section is suitable for straight-line boxes, crash-lock bottom boxes and other box types.

Produced box type Straight-line box A: 550 - 2800 mmB: 100 - 1300 mm crash-lock bottom box A: 650 - 2800 mm

B: max. 1300 mm

C: min. 120 mm

D: 40 - 200 mm 2-pieces box A: min. 550 mm

B: 100 - 1300 mm Processed materials Carton board Corrugated board Parameters

Processed materials

| Max. Carton board | 1200 g/m² |

| Corrugated flute type | E, C, B, AB, 3-layer or 5-layer |

| Max. speed | 200 m/min |

| Inching speed | 20 m/min |

| Max. Thickness of folded box | 20 mm |

| Max. Blank width | 550-1350mm per sheet |

| Feeding conveyor belt number | 8 pieces |

| Feeding conveying r belt width | 60mm |

| Total press conveyor length | 6.5 m |

| Effective press conveying length | 4.7 m |

| Length | 20.5 m |

| Width | 3.5 m |

| Height | 1.95 m |

| Weight | 14.5 Ton |

| Electrical connected load | 22.5 kW |

| Compressed air | 6 bar |

| Air compressor capacity | 30 m³/h |

| Air tank capacity | 120 L |

Feeder section Splice section Lock bottom section Lower gluing unit Folding and closing section Trombone section Press section

Scan QR to Read

Links:https://www.globefindpro.com/products/25320.html

Links:https://www.globefindpro.com/products/25320.html

Recommended Products

-

Folding and Gluing Line 1450 type Carton and Box Gluing Machine

Folding and Gluing Line 1450 type Carton and Box Gluing Machine

-

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

-

Automatic Carton Folding Gluing Line 650 type Carton Gluing Machine

Automatic Carton Folding Gluing Line 650 type Carton Gluing Machine

-

Die Cutting Foil Stamping Press 1050-FLC type Holographic Foil Stamping Machine

Die Cutting Foil Stamping Press 1050-FLC type Holographic Foil Stamping Machine

-

High Speed Folding and Gluing Line 3200 type Carton Folder Gluer

High Speed Folding and Gluing Line 3200 type Carton Folder Gluer

-

Die Cutting Machine 1050 type Flatbed Die Cutter, Automatic Die Cutting Equipment

Die Cutting Machine 1050 type Flatbed Die Cutter, Automatic Die Cutting Equipment

-

Carton Folding Gluing Creasing Line 1850 type High Speed Carton Machine

Carton Folding Gluing Creasing Line 1850 type High Speed Carton Machine

-

Automatic Carton Folding Gluing Line 1100 type Folder Gluer Machine

Automatic Carton Folding Gluing Line 1100 type Folder Gluer Machine

-

Carton Closing and Counting Line

Carton Closing and Counting Line

-

High Speed Folding and Gluing Line 1100 type Folding Carton Machine

High Speed Folding and Gluing Line 1100 type Folding Carton Machine

-

Die Cutting Foil Stamping Press 1050-F type Hot Foil Stamping Cutting Line

Die Cutting Foil Stamping Press 1050-F type Hot Foil Stamping Cutting Line

-

Folding and Gluing Line 2000 type Carton Folder Gluer Machine

Folding and Gluing Line 2000 type Carton Folder Gluer Machine