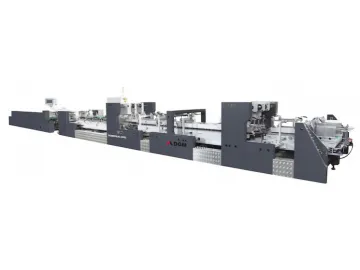

Die Cutting Machine 1050-S type Flatbed Die Cutter, Automatic Cutting Press Line

Description

The most significant characteristic of the 1050-S type flatbed die cutter is its automatic stripping capability. This die cutting system adopts a quick locking and central positioning system. It also cooperates with the cam for curvilinear movement to allow the processed waste of precise discharging.

This die cutting machine can process 7500 sheets of carton boards per hour. The maximum processed carton box reaches up to 2000 g/m². It is especially suited for large-format die-cutting of various papers, carbon boards and corrugated boards.

Processed materialsPaper

Carbon board

Corrugated board Parameters

Processed materials

| Paper | 80 g/m² |

| Maximum carbon board | 2000 g/m² |

| Maximum corrugated board | 4 mm |

| Min. Sheet size | 350 x 400 mm |

| Max. Sheet size | 740 x 1050 mm |

| Speed | 7500 sheets/h |

| Die-cutting force | 300 Ton |

| Max. Cutting size | 730 x 1040 mm |

| Min. Gripper margin | 9.5 mm |

| Feeder | 1650 mm |

| Delivery | 1300 mm |

| L x W x H | 7.1 x 4.28 x 2.45 m |

| Weight | 17 Ton |

| Power | 25 kW |

| Compressed air | 6 bar |

| Air compressor capacity | 15 m³/h |

| Air tank capacity | 100 L |

Scan QR to Read

Links:https://www.globefindpro.com/products/25342.html

Links:https://www.globefindpro.com/products/25342.html

Recommended Products

-

Outdoor Energy Saving LED Deck Light, Item SC-B101B LED Lighting

Outdoor Energy Saving LED Deck Light, Item SC-B101B LED Lighting

-

Carton Folding and Gluing Line X1100 type High Speed Carton Machine

Carton Folding and Gluing Line X1100 type High Speed Carton Machine

-

3 Flute 45°Helix Carbide End Mill

3 Flute 45°Helix Carbide End Mill

-

Carton Folding and Gluing Line 1100 type Automatic Gluing Machine

Carton Folding and Gluing Line 1100 type Automatic Gluing Machine

-

High Speed Steel Lathe Tool

High Speed Steel Lathe Tool

-

CBN Grinding Wheel

CBN Grinding Wheel

-

Box and Carton Folding Gluing Line 1100 type Folding Machine

Box and Carton Folding Gluing Line 1100 type Folding Machine

-

Die Cutting Foil Stamping Press 1050-FL type Holographic Foil Stamping Machine

Die Cutting Foil Stamping Press 1050-FL type Holographic Foil Stamping Machine

-

Folding Gluing Creasing Line 1650 type Folding Carton Gluing Machine

Folding Gluing Creasing Line 1650 type Folding Carton Gluing Machine

-

Die Cutting Foil Stamping Press 1050-FSC type Hot Foil Stamping Machine

Die Cutting Foil Stamping Press 1050-FSC type Hot Foil Stamping Machine

-

Carton and Box Folding Gluing Line 800 type Carton Machine

Carton and Box Folding Gluing Line 800 type Carton Machine

-

Die Cutting Foil Stamping Press 1050-FC type Hot Foil Stamping Cutting Line

Die Cutting Foil Stamping Press 1050-FC type Hot Foil Stamping Cutting Line