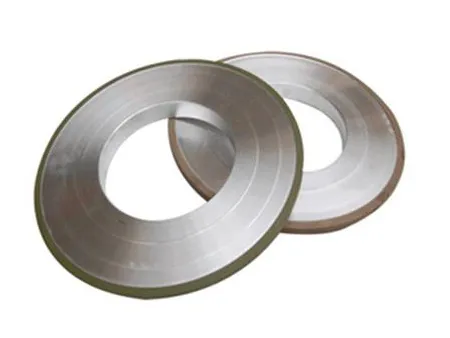

CBN Grinding Wheel

The CBN (cubic boron nitride) grinding wheel features a strong cutting force and high hardness. It is suitable for grinding high rigidity and low heat transfer materials, such as high speed steel and steel tools.

| Type of grinding wheel | Abrasive grit | Surface roughness | Application |

| Resinoid bonded grinding wheel | 100/120-170/200 | 0.16-0.63 | Used for semi-grinding, grinding, polishing and so on |

| 170/200-230/270 | 0.08-0.32 | ||

| M36/54-M10/20 | 0.04-0.16 | ||

| M10/20-M0/0.5 | 0.01-0.08 |

| Diameter (R) | Height (H) | Aperture (r) | Thickness (T) |

| 50 | 10 | 10 | 4 |

| 80 | 10 | 20 | 4 |

| 100 | 10 | 20 | 4 |

| 100 | 8 | 20 | 4 |

| 100 | 16 | 20 | 4 |

| 125 | 6 | 32 | 4 |

| 125 | 8 | 32 | 4 |

| 125 | 10 | 32 | 4 |

| 125 | 16 | 32 | 4 |

| 125 | 20 | 32 | 4 |

| 150 | 8 | 32 | 4 |

| 150 | 10 | 32 | 4 |

| 150 | 12 | 32 | 4 |

| 150 | 16 | 32 | 4 |

| 150 | 20 | 32 | 4 |

| 180 | 10 | 31.75 | 4 |

| 180 | 3 | 31.75 | 4 |

| 200 | 10 | 32 | 4 |

| 200 | 16 | 32 | 4 |

| 200 | 20 | 32 | 4 |

| 250 | 20 | 32 | 5 |

| 250 | 25 | 32 | 5 |

| 250 | 25 | 75 | 5 |

| 350 | 40 | 127 | 5 |

| 350 | 40 | 127 | 10 |

Scan QR to Read

Links:https://www.globefindpro.com/products/25353.html

Links:https://www.globefindpro.com/products/25353.html

Recommended Products

-

ER Collet, Milling Machine Collet

ER Collet, Milling Machine Collet

-

4 Flute 55°Helix Carbide End Mill

4 Flute 55°Helix Carbide End Mill

-

3 Flute 55°Helix Carbide End Mill

3 Flute 55°Helix Carbide End Mill

-

Diamond Grinding Wheel

Diamond Grinding Wheel

-

Tungsten Carbide Drill Bit

Tungsten Carbide Drill Bit

-

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

-

High Speed Steel Lathe Tool

High Speed Steel Lathe Tool

-

Carton Folding and Gluing Line 1100 type Automatic Gluing Machine

Carton Folding and Gluing Line 1100 type Automatic Gluing Machine

-

3 Flute 45°Helix Carbide End Mill

3 Flute 45°Helix Carbide End Mill

-

Carton Folding and Gluing Line X1100 type High Speed Carton Machine

Carton Folding and Gluing Line X1100 type High Speed Carton Machine

-

Outdoor Energy Saving LED Deck Light, Item SC-B101B LED Lighting

Outdoor Energy Saving LED Deck Light, Item SC-B101B LED Lighting

-

Die Cutting Machine 1050-S type Flatbed Die Cutter, Automatic Cutting Press Line

Die Cutting Machine 1050-S type Flatbed Die Cutter, Automatic Cutting Press Line