Indexable Face Mills

Indexable face mills, also known as face mill cutters, are used in milling and cutting processes for roughening and finishing of steel, stainless steel, cast iron, high temperature alloy and aluminum alloy. This milling cutter is designed to complete facing, slotting, pocketing, profiling, ramping, plunging and more.

There are 8 indexes for each seat, so that inserts can be easily changed to ensure a higher work efficiency. Face mill and end mill style inserts are both applicable.

MaterialCarbide

Types 45° Lead Angle Face Mills: These face mills are designed to be used for roughening, semi finishing and finishing of steel, stainless steel, high temperature alloy, cast iron and aluminum alloy. 45° lead angle face mills are the best choice to be used for processing workpiece surfaces with calibrations and irregular shaped semi-finished parts. 90° Indexable Milling Cutters: 90°milling cutter is used for shoulder milling, face milling and slotting. We offer a size range of 10mm to 100mm (0.375 inches to 4 inches) Specifications (90° Indexable Milling Cutter)| Model | Dimensions(mm) | ||||

| D | H | D1 | ap max | No. of Teeth | |

| Shell Mill Fixation (10mm-40mm) | 32 | 28 | 13 | 8,50 | 5 |

| 40 | 32 | 16 | 8,50 | 6 | |

| 50 | 40 | 22 | 8,50 | 7 | |

| 63 | 40 | 22 | 8,50 | 8 | |

| Shell Mill Fixation (20mm-80mm) | 40 | 32 | 16 | 11,00 | 4 |

| 40 | 32 | 16 | 11,00 | 5 | |

| 50 | 40 | 22 | 11,00 | 5 | |

| 50 | 40 | 22 | 11,00 | 6 | |

| 63 | 40 | 22 | 11,00 | 6 | |

| 63 | 40 | 22 | 11,00 | 8 | |

| 80 | 50 | 27 | 11,00 | 7 | |

| 80 | 50 | 27 | 11,00 | 10 | |

| Shell Mill Fixation (25mm-100mm) | 40 | 40 | 16 | 16,00 | 4 |

| 50 | 40 | 22 | 16,00 | 5 | |

| 63 | 40 | 22 | 16,00 | 5 | |

| 80 | 50 | 27 | 16,00 | 6 | |

| 100 | 50 | 32 | 16,00 | 7 | |

| 125 | 63 | 40 | 16,00 | 8 | |

| Shell Mill Fixation (40mm-100mm) | 40 | 40 | 16 | 15,8 | 5 |

| 50 | 40 | 22 | 15,8 | 6 | |

| 63 | 40 | 22 | 15,8 | 7 | |

| 80 | 50 | 27 | 15,8 | 8 | |

| 100 | 55 | 32 | 15,8 | 10 | |

Scan QR to Read

Links:https://www.globefindpro.com/products/25362.html

Links:https://www.globefindpro.com/products/25362.html

Recommended Products

-

Coolant ER Steel Sealed Collet

Coolant ER Steel Sealed Collet

-

HSS End Mill-4 Flute

HSS End Mill-4 Flute

-

HSS Drill Bits

HSS Drill Bits

-

2 Flute 45°Helix Carbide End Mill

2 Flute 45°Helix Carbide End Mill

-

HSS End Mill-2 Flute

HSS End Mill-2 Flute

-

Solid Carbide Slitting Saw

Solid Carbide Slitting Saw

-

Carton Folding and Gluing Line 650 type Carton Folding Machine

Carton Folding and Gluing Line 650 type Carton Folding Machine

-

4 Flute 45°Helix Carbide End Mill

4 Flute 45°Helix Carbide End Mill

-

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

-

Tungsten Carbide Drill Bit

Tungsten Carbide Drill Bit

-

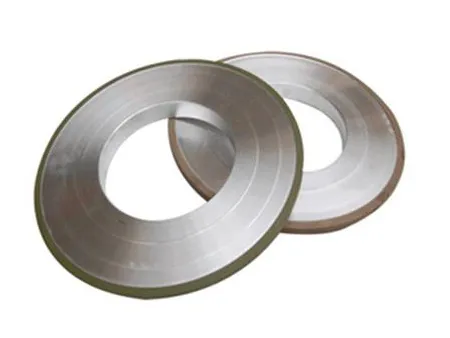

Diamond Grinding Wheel

Diamond Grinding Wheel

-

3 Flute 55°Helix Carbide End Mill

3 Flute 55°Helix Carbide End Mill

Hot Products