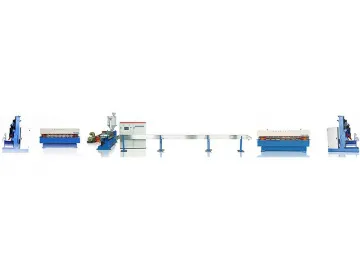

Semi-Automatic Sheet to Sheet Laminator, B Series

The Semi-automatic flute sheet to sheet laminating(mounting) machineis designed for the laminating of 175g-500g color printing paper and A/B/C/D/E/F corrugated paper, and is also suitable for the laminating of 175g-500g color printing paper and gray board paper. This machine adopts bottom sheet suction feeding unit and upper paper manually feeding unit. The paper feeding table is raised so that customers can add bottom sheet conveniently.

| Max sheet | 1100*1100mm |

| Min sheet | 350X350mm |

| Total power | 8kw |

| Max speed | 0-90m/min |

| Measurement | 8*1.77*1.75M |

| Machine weight | 3500kg |

| Max sheet | 1300*1250mm |

| Min sheet | 350X350mm |

| Total power | 8kw |

| Max speed | 0-90m/min |

| Measurement | 8*1.97*1.75M |

| Machine weight | 4000kg |

| Max sheet | 1450*1250mm |

| Min sheet | 350X350mm |

| Total power | 9kw |

| Max speed | 0-90m/min |

| Measurement | 10*2.02*1.75M |

| Machine weight | 4500kg |

(The parameters of semi-automatic flute sheet to sheet laminating(mounting) machinecan be changed according to the actual needs of the customers.)

Features The front gauge positioning system makes the positioning of the upper paper and the bottom sheet accurate. The part of the upper paper beyond the bottom sheet can be adjusted in time. Equipped with automatic glue replenishment system, the glue can be recycled and saved to avoid glue waste. The line speed of metering roller is designed to ensure uniform glue amount and avoid the glue throwing. The separate water tank is used to ensure the back of the bottom sheet is dry. Product package

Scan QR to Read

Links:https://www.globefindpro.com/products/25530.html

Links:https://www.globefindpro.com/products/25530.html

Recommended Products

-

Floating Bulletproof Vest, Soft Body Armor

Floating Bulletproof Vest, Soft Body Armor

-

Sheet to Sheet Litho Laminator with Stacker

Sheet to Sheet Litho Laminator with Stacker

-

Waterfall LED Bubble Wall

Waterfall LED Bubble Wall

-

MICH Advanced PE Bulletproof Helmet, Ballistic Helmet

MICH Advanced PE Bulletproof Helmet, Ballistic Helmet

-

Advanced Tactical Full-Protection Bulletproof Vest, Polyethylene Bullet Safe Vest

Advanced Tactical Full-Protection Bulletproof Vest, Polyethylene Bullet Safe Vest

-

Extruder Line for Power Cable, Data Cable

Extruder Line for Power Cable, Data Cable

-

FAST Advanced Aramid Bulletproof Helmet, Ballistic Helmet

FAST Advanced Aramid Bulletproof Helmet, Ballistic Helmet

-

Sheet to Sheet Mounter/Laminator with Stacker

Sheet to Sheet Mounter/Laminator with Stacker

-

Basic info:

Basic info:

-

Ballistic Blanket

Ballistic Blanket

-

Level IV Ballistic Plate BP-07D, Body Armor Plate

Level IV Ballistic Plate BP-07D, Body Armor Plate

-

Fruit & Vegetable Processing Line

Fruit & Vegetable Processing Line

Hot Products