Steel Continuous Casting Tundish of Continuous Casting System

Steel continuous casting tundish is a steel structure intermediate container connecting liquid steel ladle and the mold system. Inside it is the castables, heat-insulating shield, nozzle brick, sizing nozzle and other refractory materials. The tundish is placed on the tundish car. It plays a role in reducing and balancing the ferrostatic pressure to smooth the liquid steel flow into the mold. This helps to reduce the compact and stirring on the liquid steel inside the mold caused by the pouring liquid steel. It also traps the impurities present in the steel liquid inside the tundish and brings them to float. This avoids the impurities from flowing into the mold to influence the quality of the billet.

Precautions Because there is certain amount of liquid steel stored in the tundish, it ensures permanent continuous casting. Usually sizing nozzle is chosen as the discharge port for carbon steel continuous casting. So be careful to control the steel liquid level inside the tundish not to fluctuate widely when operating. Make sure the liquid steel height inside the tundish is no less than 300mm when changing the steel ladle. Inside the tundish is equipped with a overflow port. When accident occurs due to the sliding nozzle of the steel ladle or other reasons, discharge the molten liquid into emergency ladle to ensure the using safety of the mold system.

Scan QR to Read

Links:https://www.globefindpro.com/products/25663.html

Links:https://www.globefindpro.com/products/25663.html

Recommended Products

-

Weather Resistant Commercial Reflective Film

Weather Resistant Commercial Reflective Film

-

Invoice Printing

Invoice Printing

-

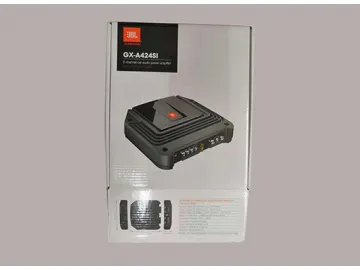

Carton Printing And Laminating

Carton Printing And Laminating

-

Corrugated Box Printing

Corrugated Box Printing

-

Sticker Printing

Sticker Printing

-

Paperboard Box Printing

Paperboard Box Printing

-

Photoluminescent Material Coating PVC Sheet Fluorescent Film (Flame Retardant)

Photoluminescent Material Coating PVC Sheet Fluorescent Film (Flame Retardant)

-

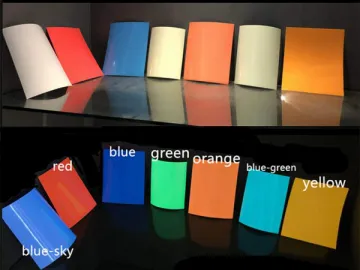

Colored Photoluminescent Film

Colored Photoluminescent Film

-

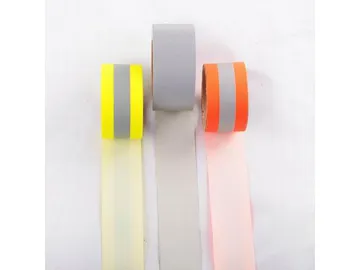

Flame Retardant Reflective Fabric

Flame Retardant Reflective Fabric

-

Continuous Casting Mold System of Continuous Casting System

Continuous Casting Mold System of Continuous Casting System

-

Spray Cooling System (Secondary Cooling) of Continuous Casting System

Spray Cooling System (Secondary Cooling) of Continuous Casting System

-

Casting Rolling Mill Of Continuous Casting Machine

Casting Rolling Mill Of Continuous Casting Machine

Hot Products