Stone Engraving CNC Router

The stone engraving CNC router is equipped with a 3-axis linkage controlling system. The worktable is made of steel material, because it has a higher hardness than stone. This stone processing machine also carries out various 2D stone engraving processes by adjusting the principle axis torque. Procedures include cutting, piercing, bottom milling and embossing. This stone equipment is also applicable for machine operations on items with less hardness, such as medium density fiberboard (MDF), PVC, acrylic, plastic plates and more.

Application

Suitable for engraving and processing gravestones, milestones, merit monuments, ceramic tiles, lithographs, jade craftworks, etc. Also suitable for processing high molecular weight polyethylene (HMWPE) notching, cutting, edge processing, PVC, acrylic, wood engraving and processing.

Materials Suitable for Processing

Metal and non-metal materials including natural marbles, artificial stones, granites, wood, high molecular weight polyethylene (HMWPE), etc.

Specifications

| Type | F7-S1325B | F7-S1530B |

| Working Stroke | 1300×2500×300mm(with alternatives) | 1500×3000×300mm(with alternatives) |

| Transmission | X/Y-Axis: Square Rail, Oblique Gear Rack; Z-Axis: Screw | |

| Drive | Step Drive | |

| Operating System | DSP Syetem | |

| Principal Axis | Air Cooling | |

| Principal Axis Power | 4.5KW | |

| Principal Axis Rotational Speed | 24000r/min | |

| Tool Holder Diameter | Φ3.175-Φ16 | |

| Weight | 1700KG | |

| Software | Type3/Artcam/Mastercam/UG | |

| Worktable | Section Bar Tool Fixture | |

| Voltage | AC380V-/220V | |

Features of Stone Engraving CNC Router

1. Machine Bed

Equipped with a thick square steel T type machine bed, the stone engraving machine is heavier. However, with a vibration treatment, there is less stress on the equipment, ensuring it is rigid and durable with a long service life.

2. StructureWorktable designed with crossbeam rib reinforcement, processed with dust-free sandblasting paint treatment, which makes it easy for cleaning. Also, the procedure increases the friction between pieces and machine bed, which makes engraving more accurate.

3. TransmissionThe 3 axes are equipped with am HIWIN (Taiwan) square linear guide rail, and the Z-axis is equipped with a TBI (Taiwan) ball screw, both of which are accurate and durable.

4. SoftwareThe machine is compatible with various CAD/CAM software, including Type3, ArtCAM, Castmate, and Ucancam.

5. Breakpoint MemorySoftware compatible is with breakpoint memory function.

6. ControllerEquipped with DSP controller, easy to monitor and control.

PEF is a high quality manufacturer of various CNC engraving routers and machining centers. For over 20 years, we have been dedicated to the development and manufacturing of CNC equipment such as CNC milling machines and CNC engraving machines to handle a number of special tasks such as 3/4/5-axis engraving processing, panel furniture processing, solid wood furniture processing, automotive parts processing, automobile model processing, mold processing, and non-metallic CNC processing.

Links:https://www.globefindpro.com/products/26020.html

-

4 Axis CNC Milling Machine

4 Axis CNC Milling Machine

-

Wood Engraving 4 Axis CNC Graver Router

Wood Engraving 4 Axis CNC Graver Router

-

Screen Plate Washing Machine

Screen Plate Washing Machine

-

Humidifier Replacement Pad

Humidifier Replacement Pad

-

Automatic Loading and Unloading Machine

Automatic Loading and Unloading Machine

-

3 Axis CNC Machining Center

3 Axis CNC Machining Center

-

3 Axis CNC Engraving Router

3 Axis CNC Engraving Router

-

Medium Efficiency Air Ventilation Bag Filter

Medium Efficiency Air Ventilation Bag Filter

-

Ozone Removal Air Filter

Ozone Removal Air Filter

-

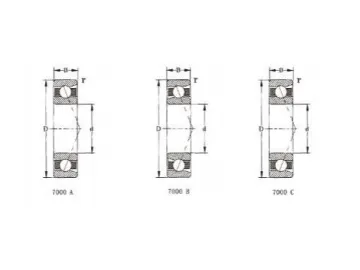

Angular Contact Ball Bearing, 7900C Series Bearing

Angular Contact Ball Bearing, 7900C Series Bearing

-

Activated Carbon Air Filter

Activated Carbon Air Filter

-

F8 Washable Air Filter

F8 Washable Air Filter