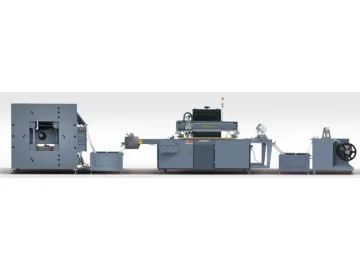

Automatic Shaped Window Patching Machine

Overview

The JB-900TC automatic shaped window patching machine carries out SMC patching after corner cutting and groove punching. This equipment is often used for window patching in various cartons after shaping and punching. It can simultaneously patch multiple parallel films, and is an ideal choice for packaging toys, cosmetics, alcohol and much more.

| Model | JB-900TC |

| Operation speed | 500-2200pcs/h |

| Max. base paper size | 900×500mm² |

| Min. base paper size | 150×100mm² |

| Base thickness (paper card) | 120-700g/cm² |

| Base thickness (corrugated paper) | Within 5mm |

| Max. plastic film size | 550×330mm² |

| Min. plastic film size | 8×12mm² |

| Plastic film thickness | 0.1-1.0mm² |

| Power | 16.1kw |

| Power supply | 3P, 380V/50Hz |

| weight | About 2000kg |

| Feeding part | 1450×1620×1386mm³ |

| printing part | 2610×1860×1375mm³ |

| patching part | 1530×1620×1855mm³ |

| pressing part | 1585×1330×990mm³ |

| pressing part | 1585×1330×790mm³ |

| overall dimension | 9074×2349×1855mm³ |

Scan QR to Read

Links:https://www.globefindpro.com/products/26076.html

Links:https://www.globefindpro.com/products/26076.html

Recommended Products

-

Automatic Scraper and Muller Machine

Automatic Scraper and Muller Machine

-

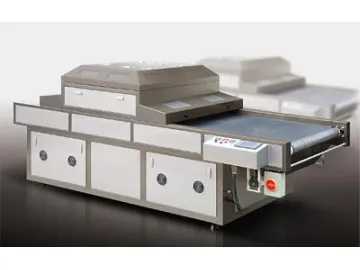

Infrared and Ultraviolet Dryer

Infrared and Ultraviolet Dryer

-

Screen Printing Ink Drying Machine

Screen Printing Ink Drying Machine

-

Screen Coating Machine

Screen Coating Machine

-

JB-1450A/1880A Fully Automatic Stop Cylinder Screen Printing Equipment

JB-1450A/1880A Fully Automatic Stop Cylinder Screen Printing Equipment

-

Horizontal Centrifugal Pump ZG Series

Horizontal Centrifugal Pump ZG Series

-

Automatic Decoating & Developing Machine

Automatic Decoating & Developing Machine

-

Fully Automatic Roll to Roll Screen Printing Press

Fully Automatic Roll to Roll Screen Printing Press

-

UV Curing Machine

UV Curing Machine

-

Computer-to-Plate Making Machine (Silk Screen Printing Version)

Computer-to-Plate Making Machine (Silk Screen Printing Version)

-

Economical Microcomputer Flat Screen Printing Machine

Economical Microcomputer Flat Screen Printing Machine

-

3/4 Automatic Screen Printing Press

3/4 Automatic Screen Printing Press

Hot Products