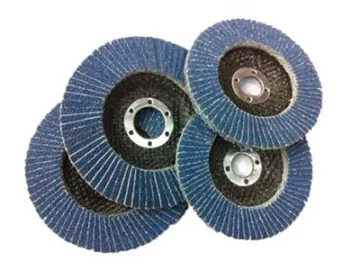

Zirconia Flap Disc

Application

Kungfu Eagle’s zirconia mop disc can be used for grinding welding joint and deburring of workpieces like metal, stainless steel, carbon steel, copper and aluminum, also for grinding and polishing glass and stone. Compared with the plastic backing, the fiberglass backing zirconia flap disc is safer, so it is recommended for high-strength industrial applications, such as metal manufacturing and construction industry.

1. Zirconia alumina has the characteristic of fast heat dissipation; thus, it can effectively prevent the workpieces from burning.

2. The flaps on the sanding disc is fully automatic overlapped by the machine, and the workmanship is neat and smooth.

3. We use zirconia alumina as the raw material of the mop disc, which has twice the sharpness and abrasive resistance of ordinary calcined sand. Meanwhile it improves the protection of the polished products.

4. The flap can be widened and thickened. For example, for a 4-inch flap disc, the general number of flaps is 72, with the length of 22mm and the width of 14mm. When the customer requests the number of flaps to be added to 80, the length and width of the flap can also be increased, usually 2-3mm is the most suitable. And the abrasive resistance can be increased by 50%.

Custom zirconia flap discs:1. Shape:

T27 flap disc (flat, suitable for normal flat objects, such as straight steel plates);

T29 flap disc (depressed center, suitable for irregular surface objects, such as stainless steel thermos)

2. Grit of abrasive cloth:

Can choose from: P36, P40, P60, P80, P100, P120, P150, P180, P240, P320,P400.

Coarse abrasive cloth (P36-P80, used for grinding, derusting and deburring rough workpieces);

Fine abrasive cloth (P100-P400, used for secondary polishing of workpieces).

3. Brand of abrasive cloth: Sanling, Kingcattle and GXK

Links:https://www.globefindpro.com/products/26308.html

-

Flexible Flap Disc

Flexible Flap Disc

-

5# Metal Zipper (Copper Zip, Open End Zip, Closed End Zip)

5# Metal Zipper (Copper Zip, Open End Zip, Closed End Zip)

-

5# Nylon Zipper

5# Nylon Zipper

-

Nylon Coil Zippers

Nylon Coil Zippers

-

Wood Cutting Chop Saw Blade

Wood Cutting Chop Saw Blade

-

Plastic Backing Flap Disc

Plastic Backing Flap Disc

-

10# Molded Plastic Zipper

10# Molded Plastic Zipper

-

Heavy Duty Nylon Zipper

Heavy Duty Nylon Zipper

-

8# Molded Plastic Zipper

8# Molded Plastic Zipper

-

Auto Interiors VOC Emission Test Chamber

Auto Interiors VOC Emission Test Chamber

-

Electric Appliance VOC Emission Test Chamber

Electric Appliance VOC Emission Test Chamber

-

Slider for Metal Zipper

Slider for Metal Zipper