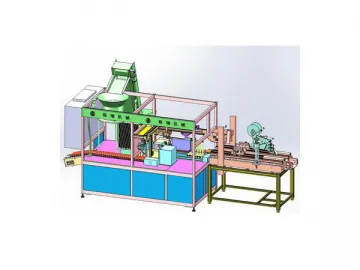

Dual Steel Brush Machine

Recommended application

This dual steel brush machine is specifically designed for the coloration correction of all kinds of flat panels that have been colored through a sponge roll. This process can make the surface coloration of panels more uniform.

The applicable products include furniture panels, wooden door plates, floors, MDF boards, inorganic panels etc.

Application site

For the production of wooden door panels.

Working principle

The dual steel brush roll rotates at a high speed through speed regulation with an inverter in order to evenly brush the surface of the panels spread with colorant.

Main parameters

| Effective processing thickness | 2-80mm |

| Effective processing width | 620/920/1320mm(optional) |

| Minimum processing length | 300mm |

| Transport speed | 0-20m/min |

| Power supply | 380V/50Hz |

| Colorant type | UV/Water-based |

Features of dual steel brush machine The panels colored by a sponge roll feature a uniform surface color after brushing by this machine. The machine brush is designed to be quickly assembled or disassembled for brush replacement and cleaning. The brush and conveying part are controlled by two independent control mechanisms that consist of motors, reducers and inverters, ensuring a high precision, excellent stability, and flexible adjustment. Automation configurations such as man-machine interface, and precision auto-elevator are available. The dual steel brush machine is capable of automated production, in order to enhance productivity and save labor.

Optional models

| Model | Effective processing width (mm) | Conveying power (kw) | Power of steel brush (kw) | Outline size (L*W*H) | |

| SR-M2620 | 620 | 0.75 | 0.75 | 1800*1850*1700 | |

| SR-M2920 | 920 | 0.75 | 0.75 | 1800*2150*1700 | |

| SR-M21320 | 1320 | 1.5 | 1.5 | 1800*2450*1700 |

Scan QR to Read

Links:https://www.globefindpro.com/products/26763.html

Links:https://www.globefindpro.com/products/26763.html

Recommended Products

-

Automatic Case Erector and Sealer

Automatic Case Erector and Sealer

-

Roller Coater

Roller Coater

-

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)

-

Horizontal High Viscosity Filling Machine

Horizontal High Viscosity Filling Machine

-

Coating Laminator

Coating Laminator

-

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Curtain Coater

Curtain Coater

-

Piston Filler with Color Mixer (high viscosity GRQY-H3-300 with sealer)

Piston Filler with Color Mixer (high viscosity GRQY-H3-300 with sealer)

-

Coating Cleaning Machine

Coating Cleaning Machine

-

Automated Feeder Roll Coating Combo Machine

Automated Feeder Roll Coating Combo Machine

-

Double Head Piston Filler (high viscosity GRQY-320X2 with sealer)

Double Head Piston Filler (high viscosity GRQY-320X2 with sealer)

-

Coating Dryer with Five UV Lamps

Coating Dryer with Five UV Lamps

Hot Products