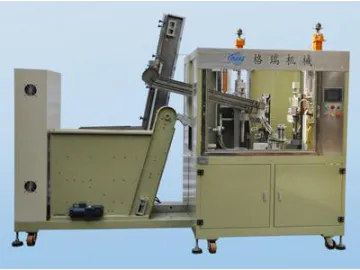

Horizontal High Viscosity Filling Machine

Application  Technical parameters

Technical parameters

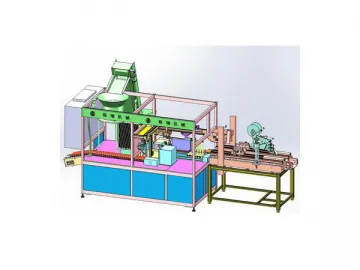

Features Horizontal filling 01: Plunger sorting mechanism

02: Plunger mould

03: Cartridge position 01: Metering mechanism

02: Filling sealant outlet With built in gas discharging device, it avoids bubble formation during capping operation.

The horizontal high viscosity filling machine is mainly used to fill high viscosity materials in plastic cartridges and paper tubes, like silicone sealant, photovoltaic sealant and so on.

DescriptionAdopting horizontal filling and horizontal end cap sealing, both operations are completed manually. Composed of a volume filling mechanism and plunger inserting mechanism, this filling machine is an economical choice.

| Filling speed | 30-40 cartridges/min. |

| Filling accuracy | ±1g/300ml |

| Filling range | 240ml-320ml (customization is offered for larger capacity) |

| Overall power | 7.0KW |

| Gas pressure | 0.7MPa |

| Gas consumption | 90L/min |

| Working pressure of hydraulic system | 6-8Mpa |

| Hydraulic cooling mode | air cooling |

| Machine size (L x W x H) | 1600x1100x1700mm |

| Net weight | 0.8T |

Features Horizontal filling 01: Plunger sorting mechanism

Filling volume is controlled manually. After filling, utilize the bottle opening to clean the filling nozzle.

Horizontal capping 01: Plunger inserting mechanism02: Plunger mould

03: Cartridge position 01: Metering mechanism

02: Filling sealant outlet With built in gas discharging device, it avoids bubble formation during capping operation.

Scan QR to Read

Links:https://www.globefindpro.com/products/26767.html

Links:https://www.globefindpro.com/products/26767.html

Recommended Products

-

Coating Laminator

Coating Laminator

-

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

-

Piston Feeder

Piston Feeder

-

Semi Automatic Vertical Piston Filler

Semi Automatic Vertical Piston Filler

-

Automatic Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Automatic Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)

-

Roller Coater

Roller Coater

-

Automatic Case Erector and Sealer

Automatic Case Erector and Sealer

-

Dual Steel Brush Machine

Dual Steel Brush Machine

-

Curtain Coater

Curtain Coater

-

Piston Filler with Color Mixer (high viscosity GRQY-H3-300 with sealer)

Piston Filler with Color Mixer (high viscosity GRQY-H3-300 with sealer)

Hot Products