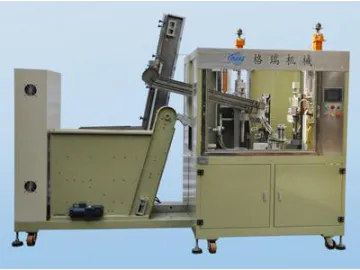

Semi Automatic Vertical Piston Filler

The semi automatic vertical position filler is suitable for filling low viscosity and high fluidity liquids, such as silicone sealant, modified saline adhesive and potting sealant, etc.

DescriptionThis piston filler has vertical structure and two filling modes. Free changeover is available for different filling materials.

Technical parameters| Filling speed | 3-6 cartridges/min |

| Filling accuracy | ±15g/2600ml |

| Filling range | 2000ml-2600ml |

| Overall power | 4.5KW |

| Gas pressure | 0.6MPa |

| Gas consumption | 60L/min |

| Working pressure of hydraulic system | 6-8Mpa |

| Hydraulic cooling mode | Circulating water cooling |

| Machine size (L x W x H) | 12000x800x2000mm |

| Net weight | 0.8T |

Note: Great is able to match the voltage and frequency of the fillers based on clients from different locations.

Features Metering system Volume filling mode is stable and reliable, with minimal metering errors. The volume can be manually adjusted. Filling deviceTwo filling modes are provided, that is bottom-up filling and opening-up filling, of free changeover.

When adopts opening-up filling, the cartridges should be plunger inserted at first. Put the cartridge on the corresponding mold with its opening up. During filling, the materials are absolutely isolated from the outside air.

If using bottom-up filling mode, the cap should be screwed firstly. Put the cartridge on the corresponding mold with the bottom up. This suits filling low viscosity and high fluidity materials.

Two plunger inserting modes are available and can be changed over freely, equipped with foot-switch control.

Links:https://www.globefindpro.com/products/26774.html

-

Automatic Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Automatic Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Tunnel Fluid Bed Coating Drying Oven (Infrared Heating)

Tunnel Fluid Bed Coating Drying Oven (Infrared Heating)

-

Single Head Piston Filler (high viscosity GRQY-3500 with sealer for silicone replacement cartridge)

Single Head Piston Filler (high viscosity GRQY-3500 with sealer for silicone replacement cartridge)

-

Coating Feeder (Putty Filling)

Coating Feeder (Putty Filling)

-

Dual Roller Coater

Dual Roller Coater

-

Three Roller Roll Coater

Three Roller Roll Coater

-

Piston Feeder

Piston Feeder

-

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

-

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Coating Laminator

Coating Laminator

-

Horizontal High Viscosity Filling Machine

Horizontal High Viscosity Filling Machine

-

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)

Three Head Piston Filler (high viscosity GRQY-320X3 with sealer)