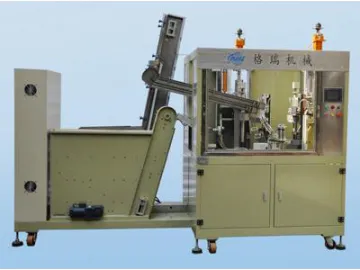

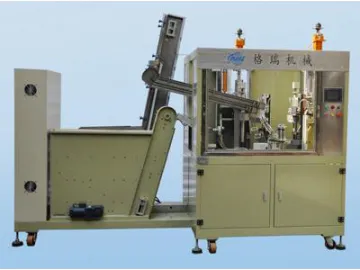

Automatic Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Application  Technical parameters

Technical parameters

02:Filling lift mechanism Automatic plunger inserting 01: Actuator A 02: Actuator B Products unload mechanism 01: Products unload mechanism After all the processes have been completed, the products are transferred by conveyor to the equipment packaging area. Filling volume adjustment is optional in manual or automatic operation. Failure warning and prompting

The automatic piston filler is mainly applied for the filling of low viscosity liquids, like industrial potting sealant, polyurethane sealant and much more.

DescriptionThe biggest feature of this automatic filler is independent dual-component filling. It can fill 25 cartridges per minute, which integrates automatic cartridge feeding, automatic plunger feeding, independent dual-component filling, plunger inserting and code-printing.

| Filling speed | 18-25 containers/min. |

| Filling accuracy | ±1g/300ml |

| Filling range | 200ml-320ml (larger capacity can be customized) |

| Overall power | 9.5KW |

| Gas pressure | 0.7MPa |

| Gas consumption | 180L/min |

| Working pressure of hydraulic system | 7-9Mpa |

| Hydraulic cooling mode | Water cooling, air cooling |

| Machine size (L x W x H) | 2840x1200x2320mm |

| Net weight | 2.0T |

Note: Great can match the voltage and frequency of the equipment depending on different customer’s locations.

Structure Automatic conveying of empty cartridge and plunger 01: Empty cartridges load bin 01: Motor 01: Motor Cartridge load bin 01: Feeding rotary mechanism Conveying mechanism 01: Rotary mechanism Two independent filling mechanisms 01:Metering mechanism02:Filling lift mechanism Automatic plunger inserting 01: Actuator A 02: Actuator B Products unload mechanism 01: Products unload mechanism After all the processes have been completed, the products are transferred by conveyor to the equipment packaging area. Filling volume adjustment is optional in manual or automatic operation. Failure warning and prompting

Scan QR to Read

Links:https://www.globefindpro.com/products/26775.html

Links:https://www.globefindpro.com/products/26775.html

Recommended Products

-

Tunnel Fluid Bed Coating Drying Oven (Infrared Heating)

Tunnel Fluid Bed Coating Drying Oven (Infrared Heating)

-

Single Head Piston Filler (high viscosity GRQY-3500 with sealer for silicone replacement cartridge)

Single Head Piston Filler (high viscosity GRQY-3500 with sealer for silicone replacement cartridge)

-

Coating Feeder (Putty Filling)

Coating Feeder (Putty Filling)

-

Dual Roller Coater

Dual Roller Coater

-

Three Roller Roll Coater

Three Roller Roll Coater

-

Hydraulic Press

Hydraulic Press

-

Semi Automatic Vertical Piston Filler

Semi Automatic Vertical Piston Filler

-

Piston Feeder

Piston Feeder

-

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

Vertical Piston Filler (low viscosity GRQL-300 with sealer for Aluminum Sealant Cartridge)

-

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

Horizontal Piston Filler (high viscosity GRQY-3500-I with sealer for Aluminum Sealant Cartridge)

-

Coating Laminator

Coating Laminator

-

Horizontal High Viscosity Filling Machine

Horizontal High Viscosity Filling Machine