Document Pocket Punching Sealing Machine with Servo Motor

The document pocket punching sealing machine is used to produce document pockets in a variety of specifications and models, making it a necessary piece of equipment for stationary production. It carries out one-time automatic completion of raw material unwinding, double fold molding, ultrasonic rolling point sealing, punching, foil stamping, transverse sealing and cutting. The pockets produced are not only smooth and beautiful, but also firmly welded.

This single line pocket production machine is suitable for PP roll materials. The single line production line is not strict with the raw material thickness, and can handle raw materials in a variety of specifications.

Process display

Raw materials Trimming Foil stamping White strip placing Edge sealing Punching Bottom sealing and cutting, Up and down interchange collector Finished products

Raw materials

Foil stamping

White strip placing

Punching

Bottom sealing and cutting, Up and down interchange collector

Finished products

Technical parameters

| Max. Cutting Size W×L | 22×20/22×9(mm) | 28×20/28×9(mm) |

| Film Thickness | 0.03mm-0.1mm | 0.03mm-0.1mm |

| Production Per Min (PC) | 60-120 | 60-120 |

| Motor | 3HP | 3HP |

| Heater | 1.5KW | 2KW |

| Power Required | 3.7KW | 4.2KW |

| Machine Dimension L×W×H | 240mm×55mm×65mm | 240mm×59mm×65mm |

| Packing Volume L×W×H | 150mm×63mm×73mm | 150mm×67mm×73mm |

| Net Weight | 1700KG | 1800KG |

| Gross Weight | 1900KG | 2000KG |

Optional accessories

Air compressor 11-hole punching die 31-hole punching die

Scan QR to Read

Links:https://www.globefindpro.com/products/27157.html

Links:https://www.globefindpro.com/products/27157.html

Recommended Products

-

Manual Gift Bag Bottom Sealing Machine

Manual Gift Bag Bottom Sealing Machine

-

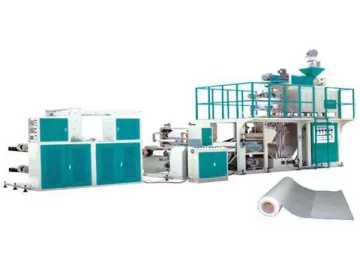

Blow Film Extrusion Line

Blow Film Extrusion Line

-

Plastic Film Recycling Granulator

Plastic Film Recycling Granulator

-

BMW Fuel Pump

BMW Fuel Pump

-

Pelletizing Machine with Plastic Recycling System

Pelletizing Machine with Plastic Recycling System

-

Oil Heated Drying Mixer

Oil Heated Drying Mixer

-

Die Cutting & Creasing Machine

Die Cutting & Creasing Machine

-

Document Sheet Protector Sealing Machine

Document Sheet Protector Sealing Machine

-

Electric Heat Sealing Machine for File Folder Pocket

Electric Heat Sealing Machine for File Folder Pocket

-

Plastic Sheet Extrusion Line

Plastic Sheet Extrusion Line

-

Jaguar Fuel Pump

Jaguar Fuel Pump

-

File Folder Creasing Machine

File Folder Creasing Machine