Carbon Steel Blade, Item CL-30 Doctor Blade

The CL-30 carbon steel blade features superior abrasion resistance compared to the CL-20 doctor blade and uses high quality, German ZAPP 2067 cold rolling carbon steel with overall performance that is 20% better than the base materials of the CL-20. This ensures the CL-30 blade effectively removes greater amounts of ink to ensure a clear printing result.

A heat treatment process has improved the durability and corrosion resistance of the blade, making it suitable for 250m/minute and higher printing press speeds, as well as for use in a variety of other printing presses to remove excess ink.

Parameter

2067element content

| C | Mn | Si | P | S | Cr |

| 1.00 | 0.3 | 0.25 | 0.025 | 0.025 | 1.5 |

Tensile strength: 1800-2000 N/mm2

Hardness: 580-600HV

Linearity: 0.15mm/1m

Advantages

The hardness levels of the CL-30 blade and CL-20 blade are the same. Blades with a high hardness reduce wear on the cylinder and anilox rollers. An improved microstructure gives the blade a better durability and reduces burrs in the blade edge. The precise polishing process prevents ink impurities from sticking to the blade surface, thus ensuring a clearer print pattern. Compared to CL-20, the blade is more stable in property and its service life can be up to 180000 cylinder rph for black printing.

Type

| Size(width) | Maximum speed | Thickness(base material) | Package | |

| 10mm | 250m/min | 0.152-0.203mm | 100m/box | |

| 30mm | 250m/min | 0.152-0.203mm | 100m/box | |

| 40mm | 250m/min | 0.152-0.203mm | 100m/box | |

| 50mm | 250m/min | 0.152-0.203mm | 100m/box | |

| 60mm | 250m/min | 0.152-0.203mm | 100m/box |

Note: The above data is standard sizes only. We can customize blade sizes according to customer requirements.

Application

Printing machine: HP, Heidelberg, Koenig&Bauer AG, Komori, Beiren, Manroland, RMGT, etc.

Coating machine: Joinfun, Graco, SATA, Anest Iwata, Hongda, etc.

Rotary printing machine: Dingli, Lisheng, Zhishang, Hengfan, Nashuo, etc.

Links:https://www.globefindpro.com/products/27279.html

-

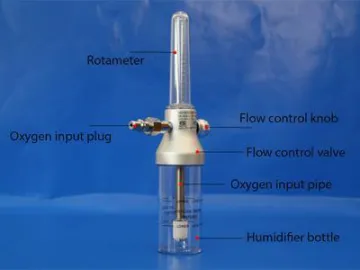

Brass Body Oxygen Flowmeter, wall connection, ABS valve stem

Brass Body Oxygen Flowmeter, wall connection, ABS valve stem

-

RZ Series Temporary Removable Strand Anchor

RZ Series Temporary Removable Strand Anchor

-

Medical Fittings

Medical Fittings

-

Type YXI Permanent Ground Anchor

Type YXI Permanent Ground Anchor

-

RZI Series Temporary Removable Strand Anchor

RZI Series Temporary Removable Strand Anchor

-

Aluminum Oxygen Flowmeter

Aluminum Oxygen Flowmeter

-

Oxygen Pressure Regulator

Oxygen Pressure Regulator

-

Aluminum Slugs

Aluminum Slugs

-

YZI Series Permanent Ground Anchor

YZI Series Permanent Ground Anchor

-

Medical Ceiling Supply Unit(Tower Type Medical Pendant)

Medical Ceiling Supply Unit(Tower Type Medical Pendant)

-

Assembled Strand Anchor System

Assembled Strand Anchor System

-

Necking Machine

Necking Machine