Annealing Oven

After that the aluminum slugs form raw stock through the cold extrusion process, the metal molecules will generate stress due the structural changes, thus the aluminum slugs lose their flexibility. In order to eliminate this stress and ensure the tube body remains applicable to usage requirements, we carry out several stress relief annealing processes on the tube shell. After the annealing process. The raw stock guarantees the adhesion of the inner and bottom coatings.

THG annealing oven

Applicable tube diameter: Φ16-Φ25mm or Φ25-Φ35mm

Production speed: 120/min

THD01 annealing oven

Applicable tube diameter: φ11mm-φ25mm or φ25mm-φ38mm

Production speed: 60/min

Scan QR to Read

Links:https://www.globefindpro.com/products/27316.html

Links:https://www.globefindpro.com/products/27316.html

Recommended Products

-

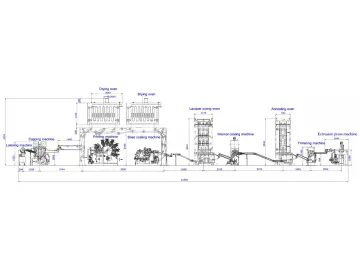

Collapsible Aluminum Tubes Line

Collapsible Aluminum Tubes Line

-

Drying Oven for Aluminum Tube

Drying Oven for Aluminum Tube

-

Internal Lacquer Oven

Internal Lacquer Oven

-

Trimming machine

Trimming machine

-

Aluminum Tube Drying Oven

Aluminum Tube Drying Oven

-

Heat Shrink Wrap Machine

Heat Shrink Wrap Machine

-

Latex Coating Machine for Aluminum Tube Sealing

Latex Coating Machine for Aluminum Tube Sealing

-

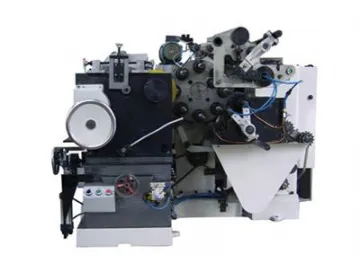

Tube Printing Machine

Tube Printing Machine

-

Latex Machine

Latex Machine

-

Impact Extrusion Press for Aluminum Tube Making

Impact Extrusion Press for Aluminum Tube Making

-

Tube Capping Machine

Tube Capping Machine

-

Tube coating machine

Tube coating machine

Hot Products