Heat Shrink Wrap Machine

The heat shrink wrap machine uses internationally advanced technology to pack products, then laminate them. This aggregate packing not only protects products against moisture, mold and damage, but also makes it easy to move and gives it an appealing aesthetic appearance.

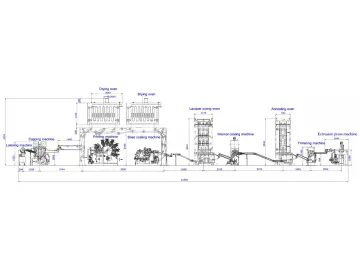

The packaging machine achieves product horizontal conveyance and propulsion, film feeding, sealing and cutting, promoting longitudinal belt, hot air heat cycling, strong cold shrinking, electricity and machine integration.

Main technical parameter Maximum diameter of heat shrinkable roller: 350mm Production rate: 10-18 toothpaste containers/minute Maximum size of packaging: 240*220*150mm Total power: 7.6Kw Dimension: 2800*800*1900mm Total weight: 650Kg Working gas pressure: 0.6Mpa Compressed air consumption: 0.6 cube/minute Working noise: 70db Suitable roller PE sheet: 0.03-0.06mm Thermal shrinkage temperature: 170-200 Length of conveyor belt: 1800mm Level of conveyor belt: 770mm Main features The machine uses a direct far-infrared radiation heating. The equipment is small, and features a short preheating time, power saving performance, and an electronic stepless speed regulation. The machine is suitable for packaging regular or irregular items. The shrink wrap does not affect packaging quality. The machine is controlled using a Siemens PLC, and color touch screen for intelligent control of all operations, as well as display of real time production speed and other information. With an excellent configuration, most of the axles adopt FESTO pneumatic components.

Scan QR to Read

Links:https://www.globefindpro.com/products/27322.html

Links:https://www.globefindpro.com/products/27322.html

Recommended Products