Coating

White Bottom Coating

Types: aluminum tubes, aluminum cans

Applications: printing coating of the aluminum tube and the aluminum can

The white bottom coating is applied in the production lines whose production speed ranges from 60/min to 220/min. You can choose coatings of different types for different production lines. The coating has great occlusion and can be blended into different colors. The standard curing condition is 160℃×6min. But we can conduct minute adjustment according to the requirements of different production lines. The coating meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

Internal Coating

Types: internal coatings of aluminum tubes and aluminum cans

Applications: printing coatings of the inner surface of the aluminum tubes

Color: gold, beige

The internal coating has great chemical resistance and is applied in hair dye and medicine. The internal coating is applied in the production lines whose production speed ranges from 60/min to 180/min. The standard curing condition is 160℃×6min. But we can do minute adjustment according to the requirements of different production lines. The coating meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

Tube End Cap Glue

Types: waterborne acrylic resin

Application: the inner surface of the aluminum tube end

The tube end cap glue kicks in bonding, sealing and leak prevention. It is divided into two types: the surface sticking type and the not sticky type. The glue is applied in the production lines whose production speed ranges from 60/min to 180/min. The standard curing condition is dry at room temperature. In winter, it can be dried forcibly under low temperature. The glue meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

Scan QR to Read

Links:https://www.globefindpro.com/products/27345.html

Links:https://www.globefindpro.com/products/27345.html

Recommended Products

-

Accumulator

Accumulator

-

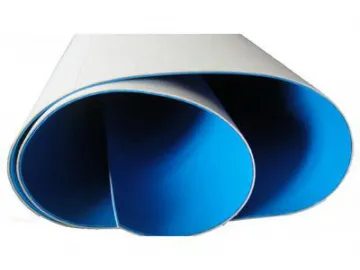

Rubber Printing Blanket

Rubber Printing Blanket

-

Accumulator

Accumulator

-

Offset printing machine

Offset printing machine

-

Plastic Caps

Plastic Caps

-

Aluminum Can Production Line

Aluminum Can Production Line

-

Electrical Lacquer Curing Oven for Aluminum Tube

Electrical Lacquer Curing Oven for Aluminum Tube

-

Drying Ovens

Drying Ovens

-

Gas Fired Lacquer Curing Oven for Aluminum Tube

Gas Fired Lacquer Curing Oven for Aluminum Tube

-

Aluminum Can Immersing & Rinsing Machine

Aluminum Can Immersing & Rinsing Machine

-

Tube coating machine

Tube coating machine

-

Printing Ink

Printing Ink

Hot Products