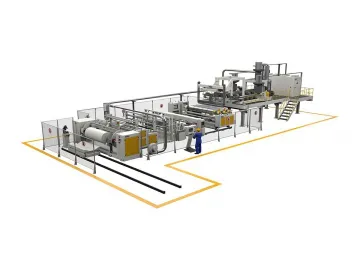

EVA/PEVA Cast Film Line

PEVA film products has various applications for shower curtain, gloves, umbrella cloth, table cloth, rain coat etc.

Line Layout Technical Parameters

| Model No. | Screw Dia. | Die Width | Film Width | Film Thickness | Line Speed |

| FME120-1900 | 120mm | 1900mm | 1600mm | 0.02-0.15mm | 180m/min |

| FME135-2300 | 135mm | 2300mm | 2000mm | 0.02-0.15mm | 180m/min |

| FME150-2800 | 150mm | 2800mm | 2500mm | 0.02-0.15mm | 180m/min |

* Remarks: Machine dimensions can be customized upon request.

OverviewThe line is well designed to produce EVA and PEVA films for various applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs. The line use EVA resin (including 30-33% VA) as raw materials to produce EVA solar battery encapsulation film. It also accepts the combination of different resin materials such as EVA, LDPE, LLDPE, and HDPE to combine their unique properties. Our cast film machine for EVA / PEVA film are specially designed for those thermoplastic polymer. The processing of EVA film and PEVA film has quite different requirements on screws, flow channels and guiding rollers. Every details of our cast film machine take all those requirements into considerations for best quality.

PEVA is polyethylene-vinyl acetate. It is made of PE and EVA. It has good softness and some elasticity. The higher the content of PE, the more difficult the adhesion is. It is generally used for film production. The ratio of these two chemicals can be adjusted to meet the needs of different applications. The higher the content of vinyl acetate (VA content), the higher the transparency, softness and elasticity will be.

FeaturesAny film width (up to 4000mm) at customer’s disposable.

Very low variation of film thickness

In-line film edge trim and recycling

In-line extrusion coating is optional

Auto film winder with different size of air shaft

Links:https://www.globefindpro.com/products/2740.html

-

P19-H4 LED Headlight

P19-H4 LED Headlight

-

CPE Cast Film Line

CPE Cast Film Line

-

EVA/POE Solar Film Extrusion Line

EVA/POE Solar Film Extrusion Line

-

Multi-layer Cast Film Line, Co-extrusion Film Machine

Multi-layer Cast Film Line, Co-extrusion Film Machine

-

Extrusion Coating Laminating Line Woven Fabric

Extrusion Coating Laminating Line Woven Fabric

-

V18K Series LED Headlights

V18K Series LED Headlights

-

PLA, PHA Biodegradable Film Extrusion Line

PLA, PHA Biodegradable Film Extrusion Line

-

Specialty Film Extrusion Line

Specialty Film Extrusion Line

-

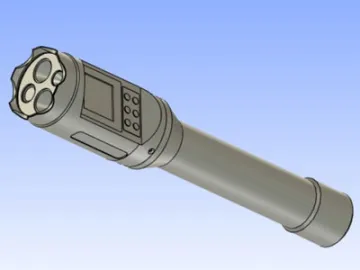

EVcam50-IR Flashlight DVR Camera

EVcam50-IR Flashlight DVR Camera

-

PETG Shrink Film Extrusion Line

PETG Shrink Film Extrusion Line

-

Hot Melt Glue Laminating & Coating Machine

Hot Melt Glue Laminating & Coating Machine

-

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series