MIG Welding Machine (Metal Inert Gas Welding)

MIG (Metal Inert Gas) welding is an arc welding process in which welding wire is applied as electrode and CO2 will be applied as shielding gas. During the welding process, a continuous solid wire electrode is first fed through a welding torch, an arc is created between the welding wire and base material and then used to melt down them, forming a weld pool, then melted welding wire flows into the weld pool acting as filler metal and weld beam is generated after the melted metal is cooled.

Our company provide different types of MIG welding machine to fulfill various requirements from different customers.

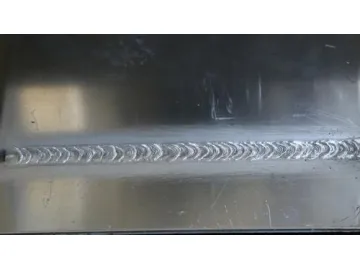

Plate material: 3mm aluminum plate

welding wire: 5356 aluminum and magnesium welding wire

welding method: fillet weld in the flat position

shielding gas: pure argon

Plate material: 3mm carbon steel plate

welding wire: solid welding wire

welding method: fillet weld in the flat position

shielding gas: mixed gas

Plate material: 4mm carbon steel plate

welding wire: solid welding wire

welding method: fillet weld in the vertical position

shielding gas: CO2

Working Principle

Wire feed rolls Welding wire Gas nozzle Contact tube Arc Shielding gas Weld pool Base materialLinks:https://www.globefindpro.com/products/27620.html

-

Digital Inverter MMA MIG TIG Welding Machine, IGBT Welder

Digital Inverter MMA MIG TIG Welding Machine, IGBT Welder

-

RF303C High Speed Winding Machine

RF303C High Speed Winding Machine

-

AC/DC Inverter TIG Arc Welder, MOSFET Welding Machine

AC/DC Inverter TIG Arc Welder, MOSFET Welding Machine

-

Manual Arc Welding Machine

Manual Arc Welding Machine

-

Inverter MMA MIG Welding Machine, IGBT Welder

Inverter MMA MIG Welding Machine, IGBT Welder

-

RF310G Two For One Twister For Filament Fibers

RF310G Two For One Twister For Filament Fibers

-

Digital AC/DC Inverter TIG Welder, IGBT Welding Machine

Digital AC/DC Inverter TIG Welder, IGBT Welding Machine

-

Arc Welding Machine

Arc Welding Machine

-

Oil HDD Drill Pipe

Oil HDD Drill Pipe

-

PCB Board Layer Stacking Machine

PCB Board Layer Stacking Machine

-

Oil PDC Bit

Oil PDC Bit

-

Multilayer Sandwich Panel Sheeting and Stacking Machine

Multilayer Sandwich Panel Sheeting and Stacking Machine