TIG Welding Machine (Tungsten insert Gas Welding)

TIG (Tungsten Inter Gas) welding is an arc welding process where argon gas is utilized to protect the welded metal. To be more specific, an inert shielding gas will continuously be expelled from the nozzle of the welding torch during the welding process, forming a protective atmosphere around the arc to protect the weld area and the electrode from oxidation or other atmospheric contamination. Our TIG welding machine can be applied for the welding of stainless steel and ferrous metals and superior quality weld seams can be ensured. A filler metal may or may not be used depending on the specific requirements for the workpiece.

Plate material: 4mm aluminum plate

welding method: fillet weld in the flat position

welding wire: 2mm aluminum welding wire

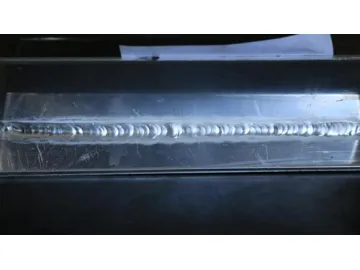

Plate material: 4mm aluminum plate

welding method: butt weld in the downhand position

welding wire: 2mm aluminum welding wire

Plate material: 3mm aluminum plate

welding method: Corner weld in the flat position

welding wire: None

Working Principle

Inert Gas Argon Gas nozzle Tungsten electrode Contact tube Welding direction Welding wire Arc Molten zone Base materialFeatures of Tungsten insert Gas Welding

Our TIG welding machine features great flexibility and adaptability. It can be applied for welding in all directions. The TIG welder also features a high duty cycle and good shape of the weld bead. It can be applied for welding materials which could not be welded with DC welding machine, such as aluminum, magnesium and related alloy. The TIG welding machine is especially used for spot welding, backing welding as well as one-side welding and both-side formation.Links:https://www.globefindpro.com/products/27629.html

-

Digital Arc Welding Machine with MMA Welding, GD Series IGBT Welding Machine

Digital Arc Welding Machine with MMA Welding, GD Series IGBT Welding Machine

-

MIG Inverter Welding Machine, IGBT Welder

MIG Inverter Welding Machine, IGBT Welder

-

MIG Welding Machine, DC MIG Welder

MIG Welding Machine, DC MIG Welder

-

MMA Welding Machine, GS Series IGBT Welding Machine

MMA Welding Machine, GS Series IGBT Welding Machine

-

MIG Welding Machine, Three Phase MIG Welder

MIG Welding Machine, Three Phase MIG Welder

-

Arc Welding Machine with MMA Welding, GT Series IGBT Welding Machine

Arc Welding Machine with MMA Welding, GT Series IGBT Welding Machine

-

RF310G Two For One Twister For Filament Fibers

RF310G Two For One Twister For Filament Fibers

-

Inverter MMA MIG Welding Machine, IGBT Welder

Inverter MMA MIG Welding Machine, IGBT Welder

-

Manual Arc Welding Machine

Manual Arc Welding Machine

-

AC/DC Inverter TIG Arc Welder, MOSFET Welding Machine

AC/DC Inverter TIG Arc Welder, MOSFET Welding Machine

-

RF303C High Speed Winding Machine

RF303C High Speed Winding Machine

-

Digital Inverter MMA MIG TIG Welding Machine, IGBT Welder

Digital Inverter MMA MIG TIG Welding Machine, IGBT Welder