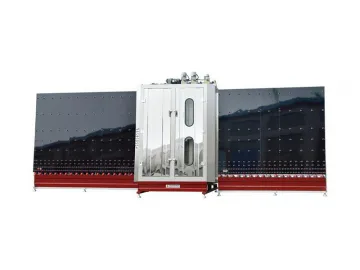

Desiccant Filling Machine

This desiccant filling machine is designed for aluminum spacer bending machines, and is controlled using a PLC control system. It can be used for the filling of automatic bent aluminum spacers and normal aluminum spacers.

Dimension: 1500×850×3650mm

Work pressure: 0.5~0.8MPa

Work Power: 220V

Flow control: about 24g/s

Filling speed: 8-12s/ (1m×1m 9a)

Aluminum spacer min: 6.5×5.5mm

Aluminum spacer max: 6.5×23.5mm

Weigh: 400Kg Feature: This desiccant filling machine can drill holes on the back of aluminum spacer, allowing it to be used for molecular sieve filling. The filling height can be adjusted according to the aluminum spacer size. The unique loading position helps to automatically fill the molecular sieve. Equipment maintenance: Check if there is water in the water separator before operating, as water needs to be regularly discharged. Check if there are impurities or water in the filter, as the filter needs regular cleaning during operation. Add oil for the air lubricator when needed. According the equipment service conditions, change the drilling bit to an electric drill when the bit is dull. Please do not adjust the speed regulating joint between the air cylinder

Scan QR to Read

Links:https://www.globefindpro.com/products/28057.html

Links:https://www.globefindpro.com/products/28057.html

Recommended Products

-

Automatic Weighing Bagging Machine

Automatic Weighing Bagging Machine

-

Gravity Paddy Separator, SLJ-MGCZ2 Grain Grader

Gravity Paddy Separator, SLJ-MGCZ2 Grain Grader

-

Multilayer Screen Separator

Multilayer Screen Separator

-

Digital Weight Bagging Machine

Digital Weight Bagging Machine

-

Vertical Glass Seaming Machine

Vertical Glass Seaming Machine

-

Vertical Glass Washing Machine

Vertical Glass Washing Machine

-

Color Sorter, STH-SDC Grain Separating

Color Sorter, STH-SDC Grain Separating

-

Double Layer Intake Gravity Separator, SLJ-TQSX Grain Cleaning

Double Layer Intake Gravity Separator, SLJ-TQSX Grain Cleaning

-

Vertical Glass Washing Machine with Dryer

Vertical Glass Washing Machine with Dryer

-

Automatic Glass Loading and Unloading Robot

Automatic Glass Loading and Unloading Robot

-

Gravity Paddy Separator, SLJ-MGCZB Grain Grader

Gravity Paddy Separator, SLJ-MGCZB Grain Grader

-

Intake Pre-Cleaning Separator, SYX-TQLM Grain and Seed Cleaning Machine

Intake Pre-Cleaning Separator, SYX-TQLM Grain and Seed Cleaning Machine