WF67Y Metal Bending Hydraulic Press Brake

Introduction  Parameters

Parameters

Optional devices

Gooseneck punch Manual refuel device Villa mechanical crowning bed Linear guide type back gauge Features The structure of the machine is welded by steel plate, and it is designed by the method of limit elements analysis. The press brake uses the method of vibration to eliminate the stress on components, making the machine stable and reliable. The two ends of the synchronization mechanism uses a high accuracy central bearing, and adds an eccentric adjusting mechanism. We use a PATRIX compensating mechanism to compensate deflection generated by the worktable and slider when running. This increases bending accuracy. The reducer motivates mechanical blocks inside of cylinder to adjust the bending angle, and the value will be displayed on the stroke counting unit. There is an adjustment button between the workbench and the wallboard, making it convenient to adjust the bending angle. There is a remote control valve on the right side of the column, which can adjust the pressure of the main system. Manual oil pump is installed on the inside of the wall plate.

The back gauge structure of the WF67K metal bending hydraulic press brake adopts a grinding plate, giving the machine high regulation accuracy and facilitating convenient operation.

| Model | 63T/2500 | 125T/3200 | 200T/4000 | 600T/8000 |

| Nominal Force KN | 630 | 1250 | 2000 | 6000 |

| Bed Length mm | 2500 | 3200 | 4000 | 8000 |

| Bed Width mm | 160 | 180 | 220 | 400 |

| Poles Distance mm | 1900 | 2600 | 3100 | 6200 |

| Throat Depth mm | 250 | 320 | 350 | 500 |

| Slider Travel mm | 120 | 120 | 250 | 300 |

| Die Loading Height mm | 345 | 380 | 500 | 630 |

| Slider travel Adjustment mm | 100 | 100 | 180 | 250 |

| Cylinder Bore mm | Φ140 | Φ190 | Φ240 | Φ400 |

| Main Power kW | 25.5 | 7.5 | 11 | 45 |

| Dimension (L)mm | 2600 | 3200 | 4000 | 8400 |

| Dimension (W)mm | 1500 | 1750 | 2150 | 3300 |

| Dimension (H)mm | 2200 | 2520 | 2950 | 5600 |

Gooseneck punch Manual refuel device Villa mechanical crowning bed Linear guide type back gauge Features The structure of the machine is welded by steel plate, and it is designed by the method of limit elements analysis. The press brake uses the method of vibration to eliminate the stress on components, making the machine stable and reliable. The two ends of the synchronization mechanism uses a high accuracy central bearing, and adds an eccentric adjusting mechanism. We use a PATRIX compensating mechanism to compensate deflection generated by the worktable and slider when running. This increases bending accuracy. The reducer motivates mechanical blocks inside of cylinder to adjust the bending angle, and the value will be displayed on the stroke counting unit. There is an adjustment button between the workbench and the wallboard, making it convenient to adjust the bending angle. There is a remote control valve on the right side of the column, which can adjust the pressure of the main system. Manual oil pump is installed on the inside of the wall plate.

Scan QR to Read

Links:https://www.globefindpro.com/products/28321.html

Links:https://www.globefindpro.com/products/28321.html

Recommended Products

-

Hydraulic Ironworker (Steel Plate Punching, Shearing, Notching Machine)

Hydraulic Ironworker (Steel Plate Punching, Shearing, Notching Machine)

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

Pneumatic Punch Press Machine

Pneumatic Punch Press Machine

-

Open Type Power Press Machine

Open Type Power Press Machine

-

Upper Roller Universal Plate Bending Machine

Upper Roller Universal Plate Bending Machine

-

Hydraulic Punching Machine

Hydraulic Punching Machine

-

WH67K(Y) series Metal Hydraulic Press Brake

WH67K(Y) series Metal Hydraulic Press Brake

-

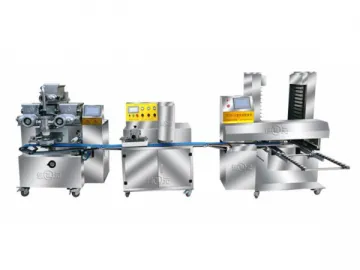

Mooncake Production Line

Mooncake Production Line

-

Steamed Bun Machine (Stuffed Buns Line)

Steamed Bun Machine (Stuffed Buns Line)

-

Automatic Dough Encrusting Machine

Automatic Dough Encrusting Machine

-

Automatic Dough Sheeting and Cutting Machine

Automatic Dough Sheeting and Cutting Machine

-

4 Column Hydraulic Press Machine

4 Column Hydraulic Press Machine