TH65 Fiber Laser Tube Cutting Machine

Compared to other pipe cutters, the TH65 fiber laser tube cutting machine has a faster running speed and acceleration, with a maximum speed of 100m/minute and a maximum acceleration up to 1.0G, which is 5 times faster than other pipe cutters.

Applicable materials: Stainless steel, carbon steel of 0.5-10mm, aluminum, brass, copper, galvanized plate, cold-rolled sheets and more.

Applicable materials: Square, circular, rectangular, oval, and special shapes such as a D shape and hexagon tube.

Application industry: This tube laser cutter is used for processing of metal sheets, kitchenware, furniture, lighting, gym equipment, automobile manufacturing and more.

Technology parameter

| Processing Area(circular tube) | Φ20mm-Φ210mm |

| Processing Area(square tube) | 20×20mm-150×150mm |

| Machinable Pipe Length | 6500mm |

| Laser power | 1000W-4000W |

| Laser Wavelength | 1070-1080mm |

| Max. moving speed | 100m/min |

| Max. acc. speed | 1.0G |

| Positioning Accuracy | 0.03mm/m |

| Reposition Accuracy | ±0.03mm |

| Power Supply | 380V/50Hz |

| Machine loading weight | 3000Kg |

| Machine dimensions | 12000mm×3500mm×2800mm |

* We offer lasers in various power levels. The materials and thicknesses to be cut directly depend on the laser power.

Compatible Materials

Stainless steel

Carbon steel

Brass

Copper

Aluminum

Galvanized steel

Cold rolled steel

Titanium

Electrolytic steel

Silicon steel

Component characteristics

Laser system We use a YLS-CUT series high power fiber laser from IPG.

Pneumatic chuck The fully automatic pneumatic chuck not only centers and clamps work pieces quickly, but also guarantees the stable holding force through pressure adjustment. Because of this, the clamping process is done with no damage to the pipe. There is no deformation to the pipes, even those that have thin walls.

Automatic material loading and unloading device The automatic material loading and unloading device is controlled using a numerical control system to feeding the pipes. The loading device will clamp a single pipe from the bundle, and send it forward to be inspected. This decreases the cost of manually delivery materials, as it can also load pipe bundles and straightly connect with the pipe cutting process.

Operation system The HSG8800 operation software is a professional operation software researched and developed independently by our company for fiber laser cutters in order to facilitate easier operation.

Rack and gear reducers In working with YCC, we are able to provide a more durable rack based on customer requirements through the customization of tungsten steel.

Links:https://www.globefindpro.com/products/28408.html

-

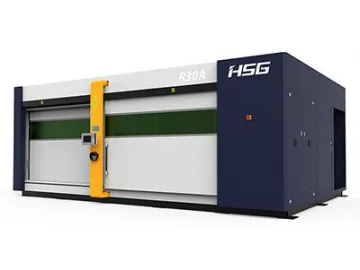

G3015A Fiber Laser Cutting Machine with Double Work Table

G3015A Fiber Laser Cutting Machine with Double Work Table

-

TS65 Fully Automatic Fiber Laser Tube Cutting Machine

TS65 Fully Automatic Fiber Laser Tube Cutting Machine

-

Fabric CO2 Laser Cutting Machine

Fabric CO2 Laser Cutting Machine

-

IPL E-light Radio Frequency Nd YAG Laser Beauty Machine

IPL E-light Radio Frequency Nd YAG Laser Beauty Machine

-

Cavitation RF Slimming Machine

Cavitation RF Slimming Machine

-

3D Laser Cutting Machines

3D Laser Cutting Machines

-

Jet Peel Water Oxygen Machine

Jet Peel Water Oxygen Machine

-

2 Head Fat Freezer Machine

2 Head Fat Freezer Machine

-

G3015B Dual Drive Fiber Laser Cutting Machine

G3015B Dual Drive Fiber Laser Cutting Machine

-

Fat Freezing Machine for Reducing Fat

Fat Freezing Machine for Reducing Fat

-

Fiber Laser Cutting Machines

Fiber Laser Cutting Machines

-

G3015C Fiber Laser Cutting Machine with Gear Rack Dual Drive

G3015C Fiber Laser Cutting Machine with Gear Rack Dual Drive