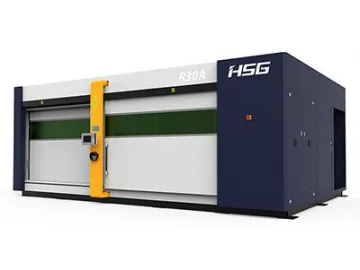

G3015A Fiber Laser Cutting Machine with Double Work Table

Within the G3015A fiber laser cutting machine with double work table, aluminum is used to produce the beam, and the laser cutter is cast under pressure. This gives the equipment a better dynamic performance and high strength, with almost no flaws such as a casting porosity. It is suitable for both long term and high power operations. Equipped with a high-low exchange platform, this laser cutting machine operates more efficiency due to the short exchange period of only 15 seconds.

Applicable materials: stainless steel, carbon steel, aluminum, brass, copper, galvanized plate and cold-rolled sheet, and more.

Application industry: The G3015A laser cutter is widely used for external processing of metal sheets, home decoration (window grilles, laser-cut screen door), elevators, aerospace components,instruments and more

Technology parameter

| Processing Area | 3000mm×1500mm |

| Laser Power | 1000W-3000W |

| Max. Cutting Speed | 140m/min |

| Max. acceleration | 1.2G |

| X/Y Positioning Accuracy | 0.05mm/m |

| X/Y Repeated Positioning Accuracy | ±0.05mm |

| Power supply | 380V 50Hz |

| Max Gross power | 10KVA (not include fiber laser generator or water chiller) |

| Machine Running Temperature | 0℃-40℃ |

| Max Running humidity | 90% |

| Whole machine weight | 7500kg |

| Machine dimensions | 8500mm×2900mm×1900mm |

* Customizable size: 4m×2m, 6m×2m, 8m×2m.

** We offer lasers in a variety of powers. The material and thickness levels to be cut directly depend on the laser power.

Compatible Materials

Stainless steel

Carbon steel

Brass

Copper

Aluminum

Galvanized steel

Cold rolled steel

Titanium

Electrolytic steel

Silicon steel

Component characteristics

Laser system IPG High power fiber laser system features powerful cutting ability.

High strength machine The metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life

Cutting headThe G3015A Fiber Laser Cutting Machine can be equipped with the laser head from German Precitec. This laser head can automatically focus in order to increase the cutting speed and ensure a smooth cutting surface.

Servo motor The electric and drive systems provided by Japan Sanyo Denki offer customers a faster rotation speed and better stability.

Rack and pinion system HSG LASER uses a rack and pinion reducer from ALPHA. Not only will it not become stuck and stop, but it can also match perfectly to various machines.

Rack and gear reducer Our company can customize tungsten steel transmission racks that are more durable, through our strategic partner YYC.

Links:https://www.globefindpro.com/products/28409.html

-

TS65 Fully Automatic Fiber Laser Tube Cutting Machine

TS65 Fully Automatic Fiber Laser Tube Cutting Machine

-

Fabric CO2 Laser Cutting Machine

Fabric CO2 Laser Cutting Machine

-

IPL E-light Radio Frequency Nd YAG Laser Beauty Machine

IPL E-light Radio Frequency Nd YAG Laser Beauty Machine

-

Cavitation RF Slimming Machine

Cavitation RF Slimming Machine

-

3D Laser Cutting Machines

3D Laser Cutting Machines

-

Medical Rapid Prototyping

Medical Rapid Prototyping

-

TH65 Fiber Laser Tube Cutting Machine

TH65 Fiber Laser Tube Cutting Machine

-

Jet Peel Water Oxygen Machine

Jet Peel Water Oxygen Machine

-

2 Head Fat Freezer Machine

2 Head Fat Freezer Machine

-

G3015B Dual Drive Fiber Laser Cutting Machine

G3015B Dual Drive Fiber Laser Cutting Machine

-

Fat Freezing Machine for Reducing Fat

Fat Freezing Machine for Reducing Fat

-

Fiber Laser Cutting Machines

Fiber Laser Cutting Machines