Double Point Mechanical Press (Nominal force: 1100kN~8000kN)

Description

The JM36 series double point mechanical press, of which the frame is welded from gantry steel plate, has the features of high precision, high strength and high rigidity. It is suitable for shearing, punching, blanking, bending and shallow drawing jobs.

Abandoning the disadvantages that the separate frames of traditional straight side presses need assembly and commissioning, the double point mechanical press is easy to install and convenient to operate. In addition, the metal stamping machine is also equipped with two-hand operation buttons and foot switch, realizing continuous, single operation specification.

| Type | JM36-110 | JM36-160 | JM36-200 | JM36-250 | JM36-315 | JM36-400 | JM36-500 | JM36-630 | JM36-800 | ||

| Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | Ⅰ | |||

| Nominal force | kN | 1100 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 6300 | 8000 | |

| Nominal stroke | mm | 5 | 6 | 7 | 8 | 8 | 10 | 10 | 10 | 10 | |

| Slide stroke | mm | 180 | 200 | 250 | 280 | 280 | 280 | 280 | 280 | 280 | |

| Number of strokes | Fixed | Times/min | 50 | 45 | 35 | 30 | 25 | 20 | 18 | 18 | 18 |

| Variable (Optional) | 35-65 | 30-55 | 25-45 | 20-35 | 20-30 | 18-25 | 15-20 | 15-20 | 15-20 | ||

| Max. die height | mm | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 | 800 | |

| Die height adjustment | mm | 90 | 100 | 110 | 120 | 120 | 120 | 120 | 120 | 120 | |

| Bolster area (F.B × L.R) | mm | 680×1650 | 760×1920 | 840×2250 | 920×2450 | 1000×2500 | 1100×2500 | 1200×2900 | 1300×3000 | 1300×3200 | |

| Bolster thickness | mm | 130 | 150 | 170 | 180 | 190 | 200 | 210 | 220 | 240 | |

| Slide area (F.B × L.R) | mm | 580×1360 | 660×1580 | 740×1900 | 820×2100 | 900×2200 | 1000×2300 | 1100×2600 | 1200×2800 | 1200×3000 | |

| Shank hole (Dia.× Depth) | mm | 3-φ60×70 | 3-φ60×95 | 3-φ60×95 | 3-φ60×95 | 3-φ70×95 | 3-φ70×95 | 3-φ80×105 | 3-φ80×115 | 3-φ80×150 | |

| Column spacing | mm | 1750 | 1970 | 2300 | 2500 | 2600 | 2700 | 3100 | 3300 | 3500 | |

| Frame side opening (F.B × Height) | mm | 650×350 | 880×500 | 930×550 | 990×650 | 990×650 | 1020×650 | 1040×700 | 1200×800 | 1200×800 | |

| Distance between bolster upper surface and floor | mm | 950 | 970 | 1000 | 1100 | 1120 | 1200 | 1250 | 1300 | 1400 | |

| Main motor power | kW | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

| Air cushion (Optional) (eject force× stroke× number) | kN×mm | 55×70×2 | 80×80×2 | 100×90×2 | 125×100×2 | 125×100×2 | 125×100×2 | 125×100×2 | 125×100×2 | 125×100×2 | |

| Outline dimension (F.B×L.R×H) | mm | 2250×2370×3500 | 2480×2590×3610 | 2680×3120×3930 | 2880×3370×4280 | 3420×3500×4665 | 3700×3650×4900 | 3850×4100×5100 | 4520×4310×6200 | 4600×4600×6450 | |

| Net weight | kg | 18000 | 20520 | 31000 | 37740 | 47000 | 52000 | 67500 | 95000 | 120000 | |

metal press, metalwork tools , metal manufacturing machine, pressing machine

Scan QR to Read

Links:https://www.globefindpro.com/products/28562.html

Links:https://www.globefindpro.com/products/28562.html

Recommended Products

-

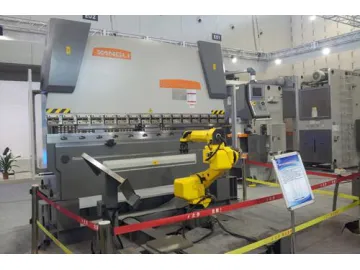

NC Press Brake

NC Press Brake

-

Transfer Press (Nominal force: 2500kN~3150kN)

Transfer Press (Nominal force: 2500kN~3150kN)

-

CNC Servo Drive Turret Punch Machine

CNC Servo Drive Turret Punch Machine

-

Servo Drive Press (Nominal force: 450kN~2000kN)

Servo Drive Press (Nominal force: 450kN~2000kN)

-

CNC Press Brake with Hydraulic Crowning System

CNC Press Brake with Hydraulic Crowning System

-

Fiber Laser Tube Cutting Machine

Fiber Laser Tube Cutting Machine

-

GL3015FT Dual Worktable Fiber Laser Cutting Machine with Tube Cutting Function

GL3015FT Dual Worktable Fiber Laser Cutting Machine with Tube Cutting Function

-

BL3015FT Fiber Laser Cutting Machine with Tube Cutting Function

BL3015FT Fiber Laser Cutting Machine with Tube Cutting Function

-

NC Hydraulic Shearing Machine

NC Hydraulic Shearing Machine

-

High Speed Press (Nominal force: 800kN~3000kN)

High Speed Press (Nominal force: 800kN~3000kN)

-

Two Stage Rotary Screw Variable Speed Air Compressor, GM series with PM Motor

Two Stage Rotary Screw Variable Speed Air Compressor, GM series with PM Motor

-

Servo Drive CNC Hydraulic Press

Servo Drive CNC Hydraulic Press

Hot Products