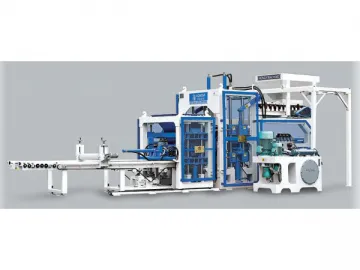

QTF10-15 Concrete Block Brick Machine

Product introduction:

The QTF10-15 concrete block brick machine has the function of layered material distribution. The main machine consists of backing material storage and distribution device, surface material storage and distribution device and jolt squeezer. This machine is suitable for producing various colorful paving bricks and landscape bricks.

Features:

1. The QTF10-15 concrete block brick machine has the advantages of functions and quality of the QT6-15 concrete block brick machine. It has additional automatic layered material distribution device. This device is movable. It can be connected with the block brick machine when producing colorful layered products. The operation can be completed within several minutes. The quantity of the surface material can be adjusted according to our customers' requirements. The distribution of the material is even and uniform, so that the brick has beautiful appearance.

2. The operation of this machine is quite simple. Only by changing the mould, it can be used for producing construction blocks, water conservancy products, curbstones etc.

Technical parameters:

| Overall dimension(mm) | 7200×2350×2850mm |

| Pallet size(mm) | 1120×880×40mm (wooden) 1120×880×25mm (PVC board) |

| Machine weight(kg) | 16800kg |

| Mode of vibration | Table and mould vibration |

| Frequency of vibration(hz) | 50-70hz |

| Molding cycle(s) | 15-25s |

| Installed capacity(kw) | 34.5kw |

Rate schedule:

| Specification of products (mm) | Number of blocks per pallet | Pieces/1 hour | Pieces/8hours | Pieces/300 day(two shifts) | ||

| Block | 390×190×190 400×200×200 | 10 | 2,400 | 19,200 | 11,520,000 | |

| Hollow Brick | 240×115×90 | 24 | 5,760 | 46,080 | 27,648,000 | |

| Paving Brick | 225×112.5×60 | 24 | 5,760 | 46,080 | 27,648,000 | |

| Standard Brick | 240×115×53 | 48 | 11,520 | 92,160 | 55,296,000 | |

Customer examples of QTF10-15 concrete block brick machine

2010.7 Fuqing: QTF10-15 paving brick machine

Algeria: QTF10-15 port load bearing brick, colorful brick and hollow brick machine

Brick application

Links:https://www.globefindpro.com/products/29270.html

-

QT12-15 Concrete Block Brick Machine

QT12-15 Concrete Block Brick Machine

-

HD28 Vertical Steam Sterilizer

HD28 Vertical Steam Sterilizer

-

Custom Filtration

Custom Filtration

-

HJ series Vertical Steam Sterilizer

HJ series Vertical Steam Sterilizer

-

LDJ series Portable Autoclave

LDJ series Portable Autoclave

-

HG series Vertical Steam Sterilizer

HG series Vertical Steam Sterilizer

-

LD series Vertical Steam Sterilizer

LD series Vertical Steam Sterilizer

-

LD series Portable Autoclave

LD series Portable Autoclave

-

Automatic Architectural Block Production Line

Automatic Architectural Block Production Line

-

YDA series Pressure Steam Sterilizer

YDA series Pressure Steam Sterilizer

-

QT6-15 Concrete Block Brick Machine

QT6-15 Concrete Block Brick Machine

-

Metal Washable Filters

Metal Washable Filters